LUOYANG DATANG ENERGY TECH CO.,LTD

Shock-Resistant PPR Pipes For Plumbing And Drainage Systems

PRODUCT PARAMETERS

Description

Introduction of Shock-Resistant PPR Pipes

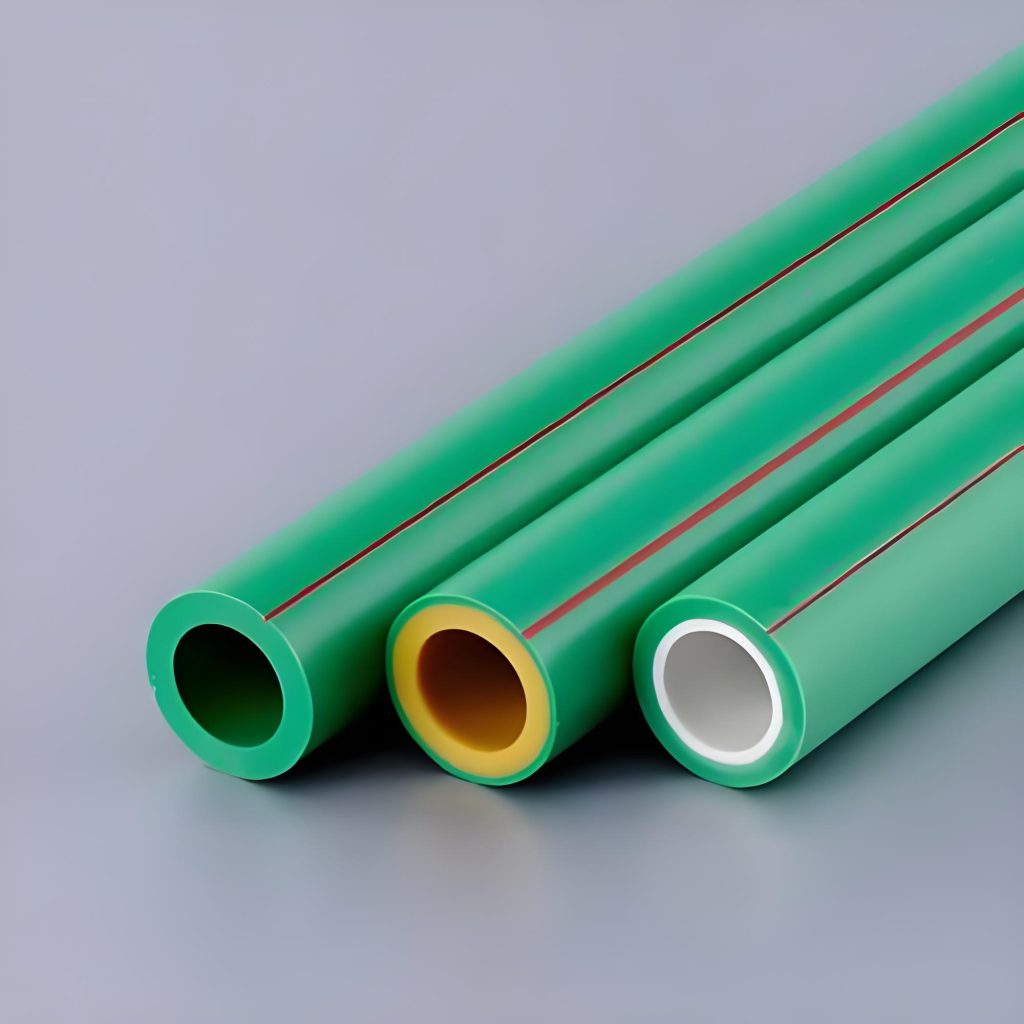

PPR (random copolymer polypropylene) pipes are high-performance plastic pipe systems specially designed for hot and cold water transportation, with high-temperature resistance (≤95℃), corrosion resistance, long life (50 years +), and other characteristics. The three-layer composite structure (outer layer UV resistance, middle layer pressure, inner layer antibacterial) is ideally suited to the high standard of building and municipal engineering in Japan.

The compulsory certification requirement of the Japanese market (the latest in 2025)

JIS A 2021 Certification: Japanese industry standard, verifying pipeline pressure (≥2.0MPa), dimensional accuracy (outer diameter error ±0.3mm), and thermal stability (95℃/1000 hours strength retention rate ≥80%).

JWWA Certification: Japan Watercourse Association drinking water safety certification requires lead and cadmium dissolution of less than 0.01mg/L and 0.005mg/L, respectively (stricter than China GB/T standard 50%).

MLIT Certification: Ministry of Soil and Transport building code certification to ensure that the pipeline is in accordance with the “Building Standards Law” Article 38 fire and seismic requirements.

Details of Shock-Resistant PPR Pipes |

Technical advantages and innovative design

Extreme security

0 Dissolution of Heavy Metals: Food-grade raw materials (in accordance with Article 30 of the Food Hygiene Law of Japan) have passed the test of the Tokyo Health and Safety Research Center.

Patented Earthquake-Resistant Design: The built-in flexible connector can withstand the shock of a 30-year earthquake cycle according to the JIS Z 8703 simulated seismic degree 7 test.

High Efficiency And Energy Saving

Heat Loss Reduced By 40%: Compared with metal pipe insulation performance 2x, suitable for geothermal heating systems in Japan.

Lightweight Installation: The DN25 pipeline weighs only 0.32kg/m (iron pipe 1.2kg/m), which reduces the construction labor cost.

The Internet of Smart Things

IoT Pipe Fitting System: Equipped with a temperature/pressure sensor, the data is directly connected to the building BIM management platform, real-time monitoring of leakage and energy consumption.

Product Structure Analysis

| Structural Layer | Material | Features |

| Outer layer | UV stabilized polypropylene | Anti-uv aging, outdoor service life ≥20 years |

| Mid-level | Glass fiber reinforced PPR | Pressure bearing capacity increased by 50%, resistant to instantaneous high pressure impact |

| Inner layer | Nano antibacterial coating | Inhibit Legionella breeding and reduce biofilm formation rate by 90% |

Specifications and Parameters of Shock-Resistant PPR Pipes

1 Standard Dimension and bearing capacity (JIS specification for the new edition 2025)

| Nominal Diameter (mm) | Outer Diameter (mm) | Wall Thickness (mm) | Working Pressure (20 ° C) | Maximum Temperature Resistance |

| DN20 | 20.4±0.2 | 2.8 | 2.5 MPa | 110 ℃ |

| DN25 | 25.5±0.3 | 3.2 | 2.3 MPa | 105 ℃ |

| DN32 | 32.6±0.3 | 4.0 | 2.0 MPa | 95 ℃ |

Environmental adaptability test data

Chemical resistance: Soaked in pH 1-14 acid and alkali solution for 1 year,

Tensile strength loss < 5%.

Low temperature brittle-resistance: No crack in impact test at -30℃ (JIS K 7111 standard).

Life verification: Passed the ISO 9080 accelerated aging test, 50 years service life certification.

Environmental adaptability test data

Chemical resistance: Soaked in pH 1-14 acid and alkali solution for 1 year,

Tensile strength loss < 5%.

Low-temperature brittle-resistance: No crack in impact test at -30℃ (JIS K 7111 standard).

Life verification: Passed the ISO 9080 accelerated aging test, 50 years service life certification.

Applications of Shock-Resistant PPR Pipes|

Japanese engineering case performance

Civil construction field

Case 1: Harumi FLAG, a high-rise apartment building in Tokyo

Application: Whole-building cold and hot water system

Results: Construction efficiency increased by 35%, annual maintenance cost reduced by 1.2 million yen.

Industrial facilities

Case 2: Pure water system at Osaka Semiconductor plant

Application: Ultrapure water conveying pipeline

Results: The resistivity was maintained at 18.2MΩ·cm (reaching the highest standard of JIS K 0557).

In the field of municipal engineering

Case 3: Fukuoka City Smart Water Renovation Project

Application: Trenchless repair of the leading pipe network

Results: The leakage rate was reduced from 25% to 3%, and it won the “2024 Innovation Award” of the Japan Waterways Association.

Packing and Shipment

Depending on the products and qty, we could make the packing of coiling, rolls, bundle packing, crates or boxes, etc.

Shipment: By sea, railway, air, or at the customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding our PPR pipes and fittings, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T, L/C at sight, Western Union & Paypal, etc.

FAQ of Shock-Resistant PPR Pipes|

FAQs for Japanese customers

Q1: Do PPR tubes comply with Japanese seismic regulations?

Fully compliant! The products have passed the BL Institute test designated by the Ministry of Land, Infrastructure and Transport, meet the requirements of the “Construction Standards Law Enforcement Order” Article 88 seismic grade 3 or above, and provide a 10-year seismic performance warranty.

Q2: Is the pipeline connection method suitable for the existing construction standards in Japan?

We support hot melt sockets and ELECTRIC melt pipe fittings, two construction methods compatible with 90% of the Japanese brand welding machines (such as RIDGID and OSAKA ELECTRIC). We also provide JIS B 2305 standard construction training.

Q3: How to cope with the extreme cold weather in winter in Japan?

DN20 and above pipelines are equipped with a standard anti-freeze layer (-35℃ anti-freeze crack) and provide the Hokkaido area’s unique anti-freeze program (including a tropical integrated system).

Q4: What are the environmental protection certifications?

Achieved:

RoHS 2.0 (Heavy Metal restrictions)

REACH SVHC 235 (EU Chemical Substances Control)

REQUEST A QUOTE

RELATED PRODUCTS

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677