LUOYANG DATANG ENERGY TECH CO.,LTD

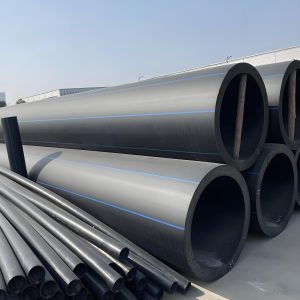

Water Supply HDPE Pipe Fitting

PRODUCT PARAMETERS

Description

HDPE (High Density Polyethylene) Pipe Fittings are components designed for joining, steering, branching or sealing polyethylene pipe systems, manufactured with high density polyethylene (HDPE) or medium density polyethylene (MDPE), perfectly compatible with PE pipes and widely used in the field of fluid transportation.

HDPE Pipe Fitting Introduction

PE (polyethylene) pipe fittings are components designed for joining, steering, branching or sealing polyethylene pipe systems, manufactured with high density polyethylene (HDPE) or medium density polyethylene (MDPE), perfectly compatible with PE pipes and widely used in the field of fluid transportation.

HDPE Pipe Fitting Advantage

1. Strong corrosion resistance: resistance to acid and alkali, salt spray and chemical medium erosion, life span of more than 50 years.

2. Flexible impact resistance: adapt to ground settlement and low temperature environment, reduce the risk of tube explosion.

3. Light and easy to install: the weight is only 1/8 of the metal pipe fittings, supporting a variety of connection methods such as hot melt and electric melt.

4. Environmental protection and non-toxic: in line with drinking water sanitation standards (such as GB/T 17219), no heavy metal precipitation.

5. Low maintenance cost: the inner wall is smooth, the friction resistance is small, and the long-term use is not easy to scale.

HDPE Pipe Fitting Specifications

Gaskets: Gaskets are like rings used to seal connections between pipes. They come in different materials and shapes depending on the type of connection you have.

Pipe Elbows: Pipe elbows help change the direction of the pipe’s flow. They come in 90-degree and 45-degree angles, and there are two types: long radius (which is smoother) and short radius (which takes up less space but causes more pressure).

Pipe Bend: Pipe bends are like gentle curves in the pipe. They’re used when you need a smooth change in direction to avoid pressure build-up. They come in different sizes, like 3D and 5D, which refer to the curve’s length.

Pipe Tee: A pipe tee looks like the letter “T” and is used to split the flow of fluid from the main pipeline. There are different types, like straight tees (which have the same diameter), reducing tees (which have smaller branches), barred tees (used in special pipelines), and wye tees (which connect pipes at a 45-degree angle to reduce friction).

Cross: A cross looks like a plus sign and has one inlet and three outlets. It’s mainly used in fire sprinkler systems, not regular plumbing.

Pipe Reducers: Pipe reducers make a pipe narrower. There are two types: concentric and eccentric. Concentric ones keep the middle of the pipe at the same height. They’re used when two different pipe sizes need to be the same in the middle of a system. Eccentric ones help keep the bottom of the pipe at a certain level, so the outside surface of the pipe stays level.

Pipe Caps: At the end of a plumbing system, there’s a cap. It covers the end of the pipe to stop leaks.

Stub Ends: Stub ends do the same thing as pipe caps but are used with lap joint flanges.

Piping Unions: These are used for pipes with low pressure that need to be taken apart often. They have three parts: a female end, a male end, and a nut. The nut, along with the female and male ends, creates a strong seal.

Pipe Coupling: There are three types: full, half, and reducing. Full couplings connect small pipes. Half couplings connect a small pipe to a large one. Reducing couplings connect two pipes of different sizes.

HDPE Pipe Fitting Technical Standards

| Project | Parameter Range | Standard |

| Material | HDPE (PE80/PE100) | ISO 4427, GB/T 13663 |

| Pressure Rating | PN6-PN25 (0.6-2.5MPa) | ISO 4065 |

| Size Range | DN20-DN1200 (1/2″-48″) | ASTM D3035 |

| Operating Temperature | -40 ° C to +60 ° C | EN 12201 |

Welding pipe fitting: suitable for DN20-DN315, voltage 39.5V±0.5V, welding time automatic calibration.

Hot melt butt fitting: DN50-DN1200, heating plate temperature 210℃±10℃, pressure stage adjustable.

Mechanical connector: stainless steel clamp type, applicable pressure ≤1.6MPa, quick installation without tools.

HDPE Pipe Fittings Application

1. Municipal Engineering

Water supply pipe network: PE Tee, Flange socket, Water hammer impact resistance, Reduce leakage rate.

Gas transmission: Yellow PE gas pipe fitting, GB15558 certification, anti-static design.

2. Industrial Scenarios

Chemical pipeline: Acid and alkali resistant four-way and elbow, supporting PP/FRP composite lining.

Mine drainage: DN800 large diameter pipe fitting, resistant to ore particle wear.

3. Agriculture and Environmental Protection

Drip irrigation system: Small-caliber PE bypass, precise distribution, water saving more than 30%.

Sewage collection: Seal ring reinforced inspection well connector, anti-leakage grade IP68.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

HDPE Pipe Fitting FAQ

Q1: How to choose the suitable PE pipe fittings specifications?

A: Step 1: Confirm the pipe outer diameter (e.g. DE110) and SDR value (e.g. SDR11).

Step 2: Select PN rating according to system pressure (e.g. PN16 corresponds to 1.6MPa).

Step 3: Select the material according to the characteristics of the medium (gas requires yellow special parts).

Q2: What are the operation points of hot melt connection?

A: Clean the pipe end to ensure that there is no oil;

Temperature of heating plate is controlled at 210±10℃;

Keep the butt pressure stage stable, do not move during cooling.

Q3: Can PE pipe fittings be mixed with PVC pipe?

A:Direct connection is not recommended. It needs to be connected through a PE/PVC adapter and mechanically sealed with a flange or thread.

Q4: Do pipe fittings support custom non-standard dimensions?

A: Yes. Provide 3D scanning mapping services, can customize DN50-DN2000 shaped parts, lead time of 15-30 days.

REQUEST A QUOTE

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677