LUOYANG DATANG ENERGY TECH CO.,LTD

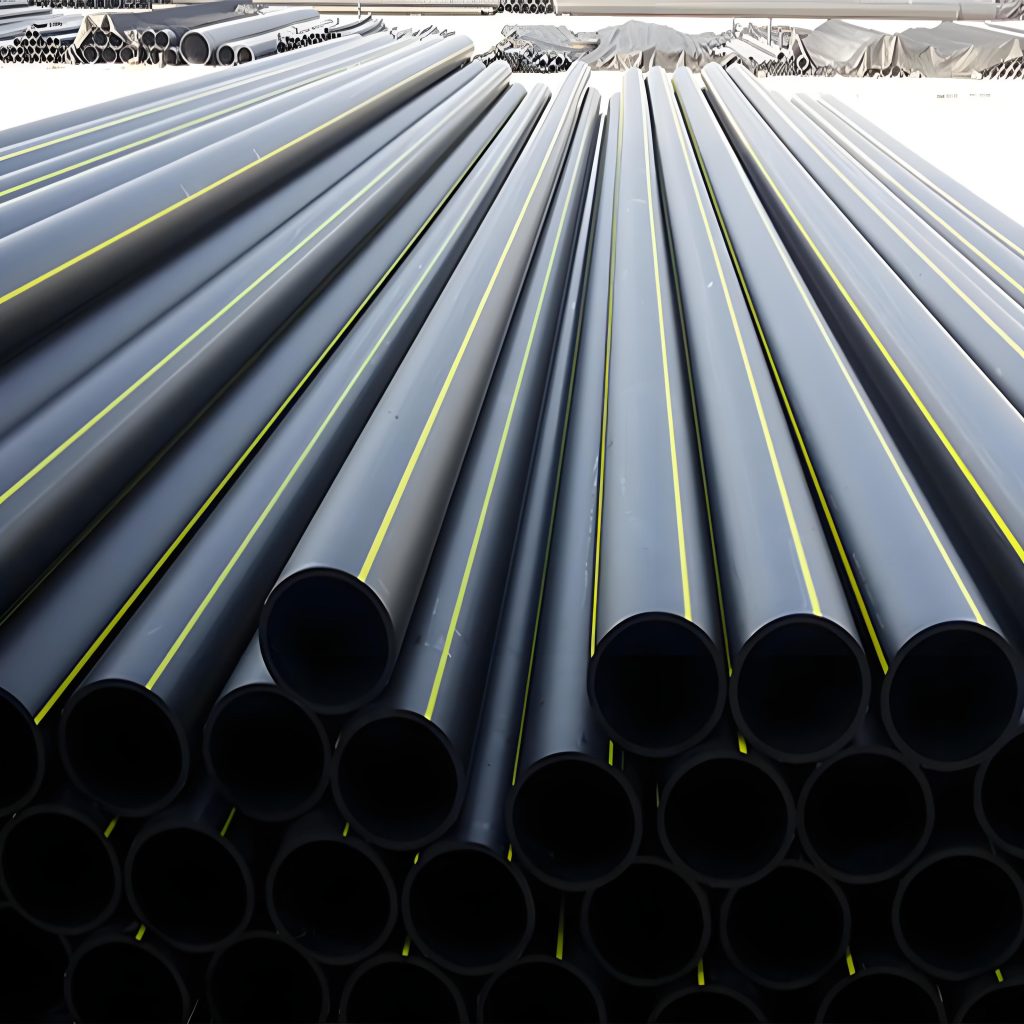

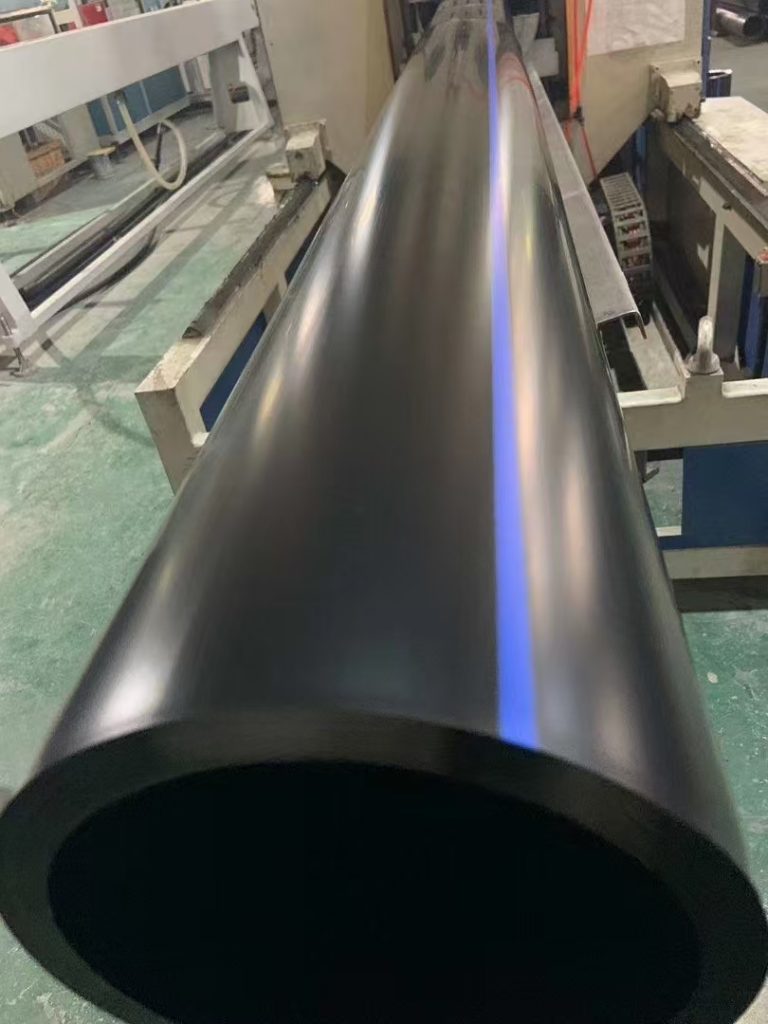

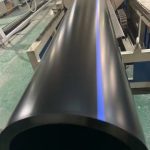

Wholesale Corrosion Resistant Industrial HDPE Pipe

PRODUCT PARAMETERS

Description

Introduction of Industrial HDPE Pipe

PE (polyethylene) water supply pipe is a kind of commonly used pipe produced by polyethylene plastic material, which has become one of the indispensable and important pipes in modern engineering construction. Polyethylene (PE) is a kind of polymer material with good corrosion resistance, aging resistance and low-temperature impact resistance, so PE piping has been widely used in water treatment, natural gas transportation, urban water supply, agricultural irrigation, oil transportation and other fields by virtue of its excellent performance.

Details of Industrial HDPE Pipe

PE Water Supply Pipes which are more commonly used in industrial and construction fields because of their higher density and compression resistance.PE pipes are also lighter in weight, which makes them easy to be transported and installed, and greatly reduces construction costs.

1. Temperature resistance: PE pipes have good temperature resistance, can be used normally at room temperature, and can withstand 50°C-60°C water temperature in a short time. For special requirements of high temperature environment, you can choose a specific type of PE pipe for installation.

2. Corrosion resistance: PE pipes have superior corrosion resistance and can resist the erosion of a variety of chemicals (such as acid, alkali, salt, etc.). Therefore, PE pipe is usually used for a variety of highly corrosive media transportation.

3. Impact resistance: PE pipe has strong impact resistance, can maintain good toughness and strength at low temperatures, which makes it can be used in harsh environmental conditions, not easy to rupture.

4. Wear resistance: PE pipe has smooth inner wall and low friction coefficient, which can effectively reduce the resistance of water flow and prolong the service life of the pipe. In addition, PE pipe has strong abrasion resistance, suitable for conveying sand, mud and other easy to wear media.

5. Anti-aging: PE pipe has good anti-aging properties, when used in ultraviolet radiation, oxidation and other environments, the pipe is not easy to age, and can maintain stable performance for a long time.

6. Environmental protection: PE pipe is made of environmentally friendly materials, in line with the requirements of recycling, so it does not pollute the environment and has good environmental performance.

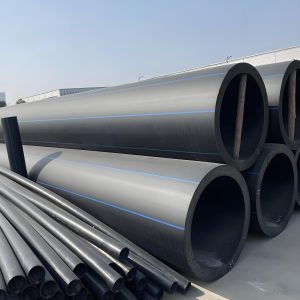

Specifications of Industrial HDPE Pipe

The specifications of PE water supply pipes mainly include the outer diameter, wall thickness, standard grade, etc.

1. Outer diameter specifications:

Small caliber pipe: the outer diameter of PE pipe ranges from 16mm to 110mm.

Medium caliber pipe: the outer diameter ranges from 110mm to 315mm.

Large caliber pipe: external diameter from 400mm to 1200mm or even larger.

PE pipes with different outside diameter specifications are suitable for projects of different sizes and uses.

2. Wall thickness specification:

The wall thickness of PE pipes is usually selected according to the outer diameter of the pipe, working pressure and other factors. Common wall thicknesses include SDR11, SDR17, SDR21, etc. SDR (Standard Dimension Ratio) is the ratio of the pipe’s outer diameter to its wall thickness. the smaller the SDR value, the thicker the pipe wall thickness and the stronger the pressure-bearing capacity.

3. Working pressure level:

The working pressure level of PE pipe is usually PN4, PN6, PN8, PN10, PN16, etc., and the unit is MPa (MPa). Pressure level selection is usually based on the use of the pipe environment and the nature of the transport medium to decide.

Note: The SDR value (Standard Dimension Ratio) is the ratio of the pipe’s outside diameter to its wall thickness; the smaller the SDR value, the thicker the pipe’s wall thickness and the greater its pressure-bearing capacity.

Pressure Rating (PN) indicates the ability of the pipe under working pressure. For example, PN10 indicates that the pipe can withstand a maximum working pressure of 10MPa.

Different specifications of PE pipes are selected according to the actual needs to ensure that they can meet the requirements of installation conditions and use environment.

Applications of Industrial HDPE Pipe

1. water supply system:

PE pipes are widely used in urban water supply, rural water pipe network construction and other fields, especially suitable for underground water supply system.PE pipes are not easy to corrode, have a long service life, is the ideal choice for water supply pipeline.

2. Drainage system:

PE pipes are also widely used in urban drainage, sewage treatment and other fields. As PE pipes have good corrosion resistance, they can resist the erosion of chemicals contained in sewage, and are widely used in sewage transportation piping systems.

3. Natural gas transportation:

PE pipes are widely used in natural gas transportation system. As the transportation of natural gas requires corrosion-resistant and pressure-resistant pipes, PE pipes have these advantages and are an important choice for natural gas transportation.

4.Agricultural irrigation:

PE pipes are used in agriculture for irrigation systems, especially sprinkler and drip irrigation systems. Its corrosion resistance, UV aging resistance and high temperature resistance make it an ideal pipe for agricultural irrigation.

5.Industrial Piping:

PE pipes are suitable for chemical, petroleum, food, pharmaceutical and other industrial fields, capable of transporting a variety of corrosive liquids, gases and solid particles.

6.Power cable protection pipe:

PE pipe as power cable protection pipe has excellent mechanical properties, which can protect the cable from external damage and extend the service life of the cable.

Packing and Shipment

Pipe dia. dn20-63mm be in coils with 100m/200m length

Pipe dia. Dn75-1200mm be packed in bars with 5.8m or 11.8m length

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding our PE (HDPE) water supply pipes and fittings, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

FAQ of Industrial HDPE Pipe

Q1. How is the corrosion resistance of PE water supply pipes?

PE pipe has excellent corrosion resistance and can resist the erosion of most chemicals, including acid, alkali, salt, sewage and so on. It is an ideal material for conveying corrosive liquids and gases.

Q2. Can PE pipe be used in low temperature environment?

PE piping has good low-temperature impact resistance and can be used normally in environments ranging from -40°C to 50°C. However, it is necessary to choose the type of piping that is suitable for use in low-temperature conditions (e.g., PE piping with added antifreeze).

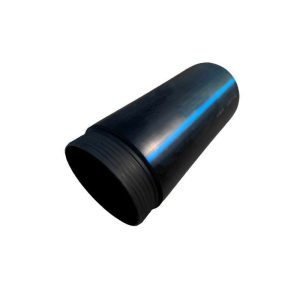

Q3. What are the connection methods for PE water supply pipes?

The common connection methods for PE pipes are heat fusion connection, electrofusion connection and mechanical connection. Thermal fusion connection is to heat both ends of the pipe to a melted state, and then pressurize the connection to form a sealed joint; electrofusion connection uses electrofusion fittings, which are connected by electric heating; mechanical connection uses flanges, threads, and other traditional ways of connection.

Q4. Can PE pipes be recycled?

PE pipes are environmentally friendly materials and can be recycled, in line with modern environmental requirements. Waste PE pipes can be recycled through reprocessing to reduce the waste of resources.

Q5. How long is the service life of PE water supply pipes?

The service life of PE water supply pipes is usually more than 50 years, and under normal use and maintenance, PE pipes can continue to provide reliable service. Its corrosion and aging resistance is strong, and it will not be easily ruptured or deformed under long-term use.

Q6. What kind of media can PE pipes transport?

PE pipes can be used to convey a wide range of media, such as clear water, drinking water, sewage, natural gas, chemicals, mud, sand, etc. Depending on the material grade of the pipe and the required working pressure, different types of PE pipes can be selected.

REQUEST A QUOTE

RELATED PRODUCTS

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677