LUOYANG DATANG ENERGY TECH CO.,LTD

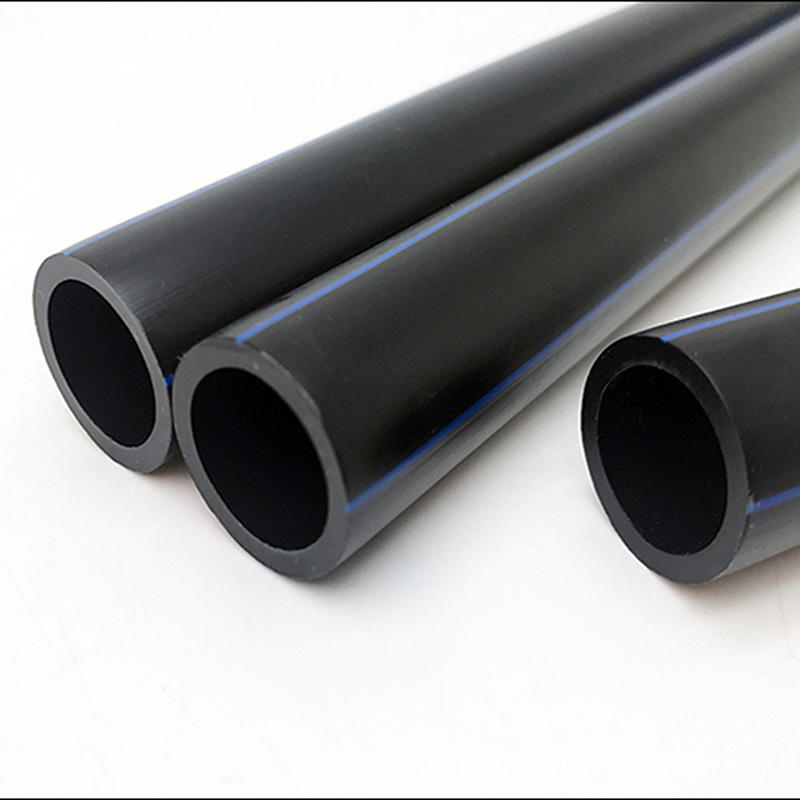

HIGH QUALITY HDPE PIPES FOR GEOTHERMAL SYSTEM

PRODUCT PARAMETERS

Description

HDPE Geothermal Pipe

Introduction of HDPE Geothermal Pipe

HDPE geothermal pipe is made of high-density polyethylene ,which is currently produced from compounds with pipe material designation codes of PE 3608 or PE 4710, and a color and ultraviolet stabilizer code of C or E, per ASTM D3350.

HDPE geothermal pipe is available in both IPS (iron pipe size) and CTS (copper tube size) sizes. IPS sizes are more common in geothermal ground loop applications. HDPE tubing and pipe are produced in coils and straight lengths.

Details of HDPE Geothermal Pipe

HDPE geothermal pipe is the preferred option for residential and commercial geothermal systems because it is more readily available and generally costs less.it has following characteristics:

- Available in wide range of sizes and wall thicknesses

- Flexible

- Heat Fusible

- Ductile

- Impact resistance

- Abrasion resistant

- Corrosion resistance

- Chemically resistant

Specifations of HDPE Geothermal Pipe

HDPE geothermal pipe is made from high quality PE4710 resin.It is the go-to material for heavy-duty water applications, with a service life of over 50 years. The material is flexible, durable and resists chemicals and cracking. It can handle geothermal heat transfers without degrading and has good hydrostatic strength. PE4710 is pressure rated to a temperature of 140°F.

| dn | pressure(mpa) | thickness | length(m) |

| 20 | 1.6 | 2.3 | 100-200 |

| 25 | 1.6 | 2.3 | 100-200 |

| 32 | 1.6 | 3.0 | 100-200 |

| 40 | 1.6 | 3.7 | 100-200 |

Applications of HDPE Geothermal Pipe

The wide application of HDPE geothermal pipe makes it an indispensable component in geothermal energy development, and it is mainly used in the following fields:

1. Geothermal heating system

In the geothermal heating system, HDPE geothermal pipe conducts geothermal energy to the interior of the building through a closed-loop pipeline network arranged underground to provide heating. Compared with traditional heating methods, geothermal heating does not require the use of fuel, can achieve zero emissions, and the heating effect is uniform and comfortable.

2. Geothermal cooling system

In addition to heating, it can also be used in geothermal cooling systems. Geothermal energy can not only be used for heating, but also for cooling by utilizing the low temperature characteristics of geothermal sources. The operating principle of the geothermal cooling system is to bring the geothermal source to the place where cooling is required through an underground pipeline system to achieve the purpose of lowering the temperature, which has the characteristics of energy saving and environmental protection.

3. Geothermal heat pump system

HDPE geothermal pipes are widely used in geothermal heat pump systems. Geothermal heat pumps are an efficient renewable energy system that exchanges heat with groundwater or soil through underground HDPE pipes to provide heating, cooling and hot water. This system is not only low-cost to operate, but also environmentally friendly.

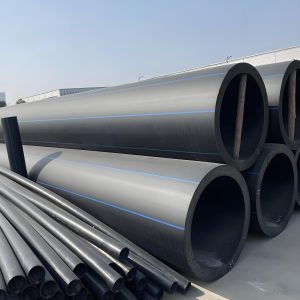

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co.Ltd was established in 2015 and located in High-tech development zone, Luoyang City, covers a large area with state-of-the-art facilities. Our government offers a supportive environment, including convenient transportation and access to essential resources. Since inception in 2015, we have been committed to excellence in pipes and fittings, continuously innovating to meet market demands.

If you need PPR Pipes and Fittings,Please feel free to contact us(sales@pipesandfittings.net)

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

FAQ of HDPE Geothermal Pipe

1. Corrosion resistance

Q1,What are the advantage of HDPE geothermal pipes?

HDPE material has very good corrosion resistance. HDPE geothermal pipes can work stably for a long time in high temperature and acid-base environment, and are not easily corroded by moisture, oxygen or other chemicals. This enables HDPE geothermal pipes to ensure long-term and stable use in geothermal systems, reducing maintenance costs and the need for frequent pipe replacement.

2. Good thermal stability

HDPE geothermal pipes have strong thermal stability and can withstand higher temperatures in geothermal energy systems. The water temperature in geothermal heating systems is usually higher than 40°C. HDPE pipes can run for a long time in high temperature environments without deformation, and are not prone to problems caused by thermal expansion.

3. High mechanical strength and toughness

The high mechanical strength of HDPE pipes enables them to withstand greater pressure and external physical shocks during installation and use. Its toughness enables it to maintain a certain degree of flexibility and is not easy to break even at low temperatures or under external force shocks.HDPE geothermal pipes can effectively resist these pressures.

4. Anti-ultraviolet ability

HDPE material itself has a certain anti-ultraviolet ability, which is particularly suitable for open-air or shallowly buried geothermal pipe systems during installation. Even under sunlight, the surface of HDPE pipes is not easy to age and become brittle, ensuring its long-term stable operation.

5. Low thermal conductivity

The low thermal conductivity of HDPE means that the pipe has less heat loss in the geothermal system, and can effectively transfer heat to where it is needed without easily causing efficiency loss due to heat loss. This is particularly important for geothermal heating systems, which can improve the energy efficiency of the entire system.

6. Easy installation and short construction period

HDPE geothermal pipes are lighter than metal pipes and are easy to transport and install. The connection method of HDPE pipes is usually hot-melt welding or electric fusion connection. These connection methods ensure that there is no leakage at the connection of the pipe and have high sealing and safety. Since the HDPE pipe itself is light in weight, the labor cost and equipment requirements can be greatly reduced during the construction process, shortening the construction period.

Q2,What is the difference between HDPE geothermal pipe and other types of geothermal pipe?

1,High-Density Polyethylene (HDPE)

HDPE made from high quality PE4710 resin is the go-to material for heavy-duty water applications, with a service life of over 100 years. The material is flexible yet durable and resists chemicals and cracking. It can handle geothermal heat transfers without degrading and has good hydrostatic strength. PE4710 pipe is pressure rated to a temperature of 140°F.

2,Polyethylene of Raised Temperature (PE-RT)

PERT is also HDPE pipe made from PE4710 resin except this resin has a pressure rating also established at 180°F. The pressure ratings of normal PE4710 pipe and PE-RT pipe are the same at a temperature of 140°F and below.

Of the three different materials, PE4710 offers the most advantageous characteristics for day-to-day operations and long-term business needs.

3,Crosslinked Polyethylene (PEX)

PEX is cross-linked polyethylene and is pressure rated to 200 °F. PEX has slightly lower pressure ratings than PE4710 and PE-RT at temperatures below 180°F.

Q3,What is the cost of HDPE geothermal pipe?

The cost of HDPE geothermal pipes depends on the diameter, length, and additional features (such as protective coatings). Generally, HDPE is more cost-effective than copper or other metallic pipe options, making it a popular choice for geothermal installations.

REQUEST A QUOTE

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677