LUOYANG DATANG ENERGY TECH CO.,LTD

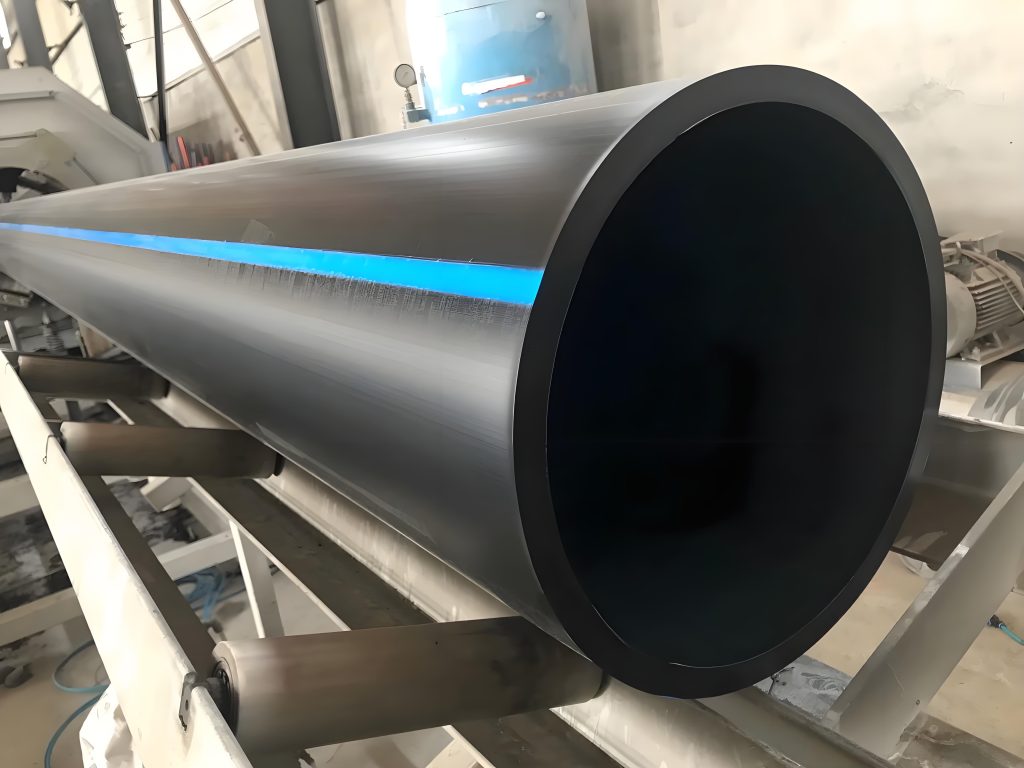

High-Pressure HDPE Pipes for Firefighting Systems

PRODUCT PARAMETERS

Description

Introduction of High-Pressure HDPE Pipes

High-Pressure HDPE Pipes is a pipeline product produced by advanced extrusion process with High Density Polyethylene (HDPE) as the main raw material. Due to its excellent physical properties and chemical stability, HDPE water supply pipeline is widely used in water supply and drainage, agricultural irrigation, municipal water supply, industrial liquid transportation and other fields.

Strong corrosion resistance: HDPE material has very high chemical stability, can effectively resist a variety of acids, alkali, salt and other corrosive media erosion.

Flexibility and impact resistance: The product has good flexibility and impact resistance, and can maintain excellent performance even in low temperature environment, reducing the risk of fracture caused by temperature difference.

Environmental protection and energy saving: no harmful substances are added in the production process, the product can be recycled and reused, in line with European and international environmental protection standards.

Convenient installation: The use of hot melt connection technology, to achieve fast and firm pipeline connection, reduce the construction cycle and installation costs.

High sealing: In the case of internal and external pressure, the pipe connection can maintain a very high sealing, to ensure the safe and stable operation of the water supply system.

Details of High-Pressure HDPE Pipes

1. Material and process

High-Pressure HDPE Pipes is mainly made of high-density polyethylene raw materials, produced by the international leading twin-screw extrusion equipment. In the production process, we have introduced a fully automated production line to ensure that each pipe in the production process of temperature control, stretching, cooling and other links have reached the optimal state, so that the product has stable physical properties and chemical characteristics.

2. Product structure

The whole High-Pressure HDPE Pipes adopts seamless design, the pipe wall thickness is uniform and the strength is high, and it can withstand greater internal and external pressure. The appearance of the product is smooth, after special anti-ultraviolet treatment, not only strong weather resistance, but also effectively prevent the aging problem caused by the sun and wind.

3. Connection method

High-Pressure HDPE Pipes connection technology we provide mainly includes two ways: hot melt butt and mechanical connection. Hot melt butt technology uses high temperature to quickly melt the pipe interface to achieve seamless docking; The mechanical connection uses special accessories and sealing rings to achieve reliable connection and meet the installation needs of different scenes.

4. Quality inspection

In order to ensure the safety and durability of products during transportation, storage and installation, we carry out strict quality testing on each batch of products, including:

Appearance inspection: check whether there are bubbles, cracks or non-uniformity on the surface of the pipeline;

Physical performance test: the tensile strength, pressure resistance, impact toughness and other indicators of the pipe are tested;

Chemical stability test: test the corrosion resistance of the product in various chemical media;

Temperature adaptability test: to ensure that the pipeline can work stably in both low and high temperature environments.

5. International certification

high quality PE pipe produced by our factory has passed a number of international certifications, including ISO 9001 quality management system certification, CE certification, etc., to ensure that products meet the technical standards and safety specifications of the European and global market. Through these certifications, our products have been widely recognized and highly trusted in the European market.

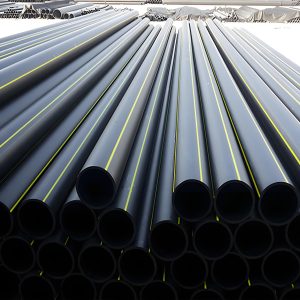

Specifications of High-Pressure HDPE Pipes

1. Conventional Specifications

Diameter range: from 20mm to 630mm, different sizes of pipes can be customized according to customer needs;

Pipe wall thickness: set according to pipe diameter and use pressure requirements, usually ranging from 1.5mm to 20mm, to ensure normal use under high pressure environment;

Length: Generally supplied in 6 meters, 12 meters or custom lengths to meet the installation needs of long-distance water supply systems.

2. Pressure Rating

High-Pressure HDPE Pipes can be divided into the following models according to the working pressure:

PN6 Pipe: suitable for low pressure water supply system, mainly used in agricultural irrigation and municipal water supply system;

PN10 Pipe: medium pressure use, suitable for industrial and municipal water supply projects;

PN16 Pipe and above: suitable for high pressure water supply system, especially industrial use and special engineering projects with high safety.

3. Surface Treatment

Anti-ultraviolet treatment: anti-ultraviolet additives are used on the surface of some specifications of the pipeline to extend the service life of the pipeline in outdoor environment;

Color choice: the color of the pipeline can be customized according to customer needs, generally black, blue or gray, which is both beautiful and practical.

4. Special Customization

We can also provide customized services according to the special needs of customers, such as:

Special connection head: to meet the connection requirements of special occasions;

Thickened pipe: used in projects requiring higher compression and durability;

Special identification: printing project numbers, batch information or other identifying marks to facilitate project management and tracking.

Through a variety of specifications and customized services, our products can meet the requirements of various projects from small agricultural irrigation to large municipal projects and industrial high-pressure water transmission, providing customers with a full range of technical support and quality product assurance.

Application of High-Pressure HDPE Pipes

High-Pressure HDPE Pipes has a very wide range of applications, mainly including but not limited to the following aspects:

Municipal water supply system

In the urban water supply system, High-Pressure HDPE Pipes is often used as the main pipe of tap water network, underground water supply pipeline and small and medium-sized water plant because of its excellent corrosion resistance and high tightness. Its light weight and easy installation characteristics greatly reduce the construction costs and maintenance costs, and ensure the long-term stable operation of the water supply system.

Industrial HDPE pipe

In the industrial field, the corrosion resistance and high pressure resistance of pipelines are very strict. HDPE water supply pipeline can be used to transport a variety of industrial liquids, including chemicals, oil products, waste water, etc., in meeting the strict industrial standards, but also to ensure environmental protection and operational safety.

HDPE Agricultural Pipes

In the field of agricultural irrigation, PE pipes are widely used in large area irrigation systems because of their corrosion resistance, wear resistance and good flexibility. The pipeline system is easy to install, can adapt to the complex terrain conditions in rural and mountainous areas, and help farmers achieve efficient and water-saving irrigation management.

Building water supply and drainage system

The requirements of modern buildings for water supply systems are constantly increasing, and HDPE pipes not only perform well in the water supply system, but also apply to the drainage system inside the building. Its anti-aging and wear-resistant characteristics ensure the long-term reliable operation of the building water supply and drainage system.

Environmental protection water supply pipe

Environmental protection water treatment system

With the improvement of environmental awareness and the implementation of environmental protection policies, more and more water treatment plants and environmental protection projects have begun to use HDPE water supply pipes. Because it does not contain harmful substances and can be recycled, the product has been widely used in environmental protection projects, such as sewage treatment, rainwater collection and other systems have excellent performance.

Special Application Scenarios

In some special engineering projects, such as high altitude areas, extremely cold areas and Marine engineering, HDPE water supply pipeline has become the first choice of many engineers with its excellent low temperature resistance and impact resistance. Whether under high pressure or extreme environment, HDPE water supply pipeline can maintain stable performance to ensure the smooth progress of the project.

Packing and Shipment

Pipe dia. dn20-63mm be in coils with 100m/200m length

Pipe dia. Dn75-1200mm be packed in bars with 5.8m or 11.8m length

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding our PE (HDPE) water supply pipes and fittings, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

FAQ of High-Pressure HDPE Pipes

Q1: Which working environment is PE(HDPE) water supply pipe suitable for?

A1: HDPE water supply pipes are suitable for a variety of environments, including municipal water supply, industrial infusion, agricultural irrigation and internal building drainage systems. Its resistance to corrosion, high pressure and low temperature makes it stable in a wide range of extreme environments.

Q2: What are the advantages of HDPE pipes compared with traditional metal pipes?

A2: HDPE pipeline compared with the traditional metal pipeline has the advantages of light weight, not easy to rust, corrosion resistance, convenient installation, easy maintenance, long service life and so on. Especially in complex underground or underwater projects, the flexibility and impact resistance of HDPE pipelines are more prominent.

Q3: How to ensure the connection quality of the pipeline?

A3: Our pipe connection adopts two methods: hot melt butt joint and mechanical connection, which have passed strict quality inspection. The hot melt butt technology can achieve seamless connection and ensure that the interface is sealed firmly; And the mechanical connection uses special sealing ring and high-precision accessories to ensure that the connection is stable and durable during the installation process.

Q4: How is the environmental protection performance of the product?

A4: The high-density polyethylene raw materials we use are in line with international environmental standards and do not contain harmful substances. There is no waste gas and waste water discharge in the production process, and the products can be recycled, which meets the increasingly strict environmental protection requirements in Europe and the world.

Q5: How to choose the suitable pipeline specifications for my project?

A5: The selection of pipeline specifications requires comprehensive consideration of the water supply pressure, transportation distance and use environment of the project. We suggest that customers choose the appropriate pipeline type according to the specific requirements of the project after consulting professional and technical personnel. Our technical team will provide detailed parameter suggestions and customized services according to your needs.

Q6: How about the after-sale service?

A6: We always adhere to the “customer first” service concept. From product selection, technical consultation to after-sales installation guidance, we will provide comprehensive and professional services. If you encounter any technical problems after product delivery, our after-sales team will respond in time and provide on-site support or remote solutions to ensure the smooth progress of the project.

REQUEST A QUOTE

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677