LUOYANG DATANG ENERGY TECH CO.,LTD

HIGH QUALITY HDPE GAS PIPE

PRODUCT PARAMETERS

Description

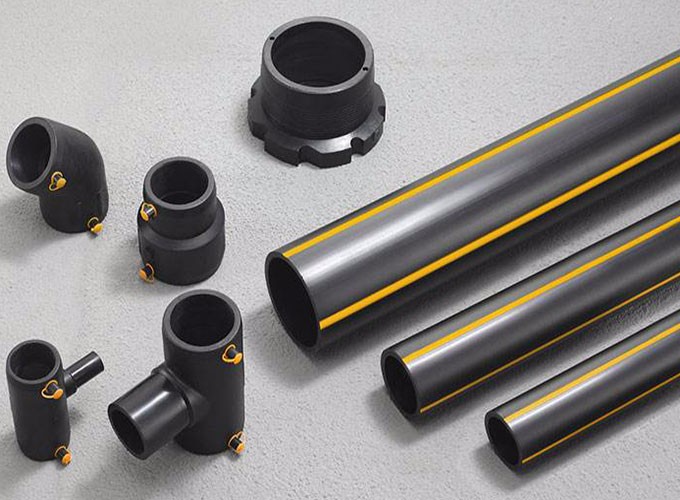

Introduction of HDPE Gas Pipe

HDPE Gas Pipe is widely used in city gas transportation projects, including natural gas, liquefied petroleum gas, biogas and other gas transportation. Its excellent performance makes the gas pipe has higher safety and stability in the city gas transportation, reducing the risk of accidents.

HDPE Gas Pipe produced by our company with top quality, great selection and expert advice service. You can rest assured to buy the products with our factory. And we will offer you the best after-sale service and timely delivery.

We generally adopts TOP QUALITY raw materials from worldwide reputed factories.As we know material of excel performance is one of the qualification with produce the topping piping system.

Details of HDPE Gas Pipe

Raw Materials:

1,PE80: PE80 Pipe refers to a gas pipeline fabricated from PE80-grade polyethylene material. PE80 indicates the grade of the polyethylene material, where “80” represents the pressure grade of the material, namely, the pressure strength that the material is capable of withstanding.

2,PE100: PE100 grade pipes comply with ISO 4427 and EN12201 standards, have a high molecular weight, a density greater than 0.94g/cm³, and have excellent impact resistance, aging resistance, and corrosion resistance.The pressure bearing capacity of PE 100 Pipes is 10-11.19mpa, and it has the advantages of good pressure resistance, thin pipe wall, high strength, and high safety factor.It can be used as a gas transmission pipe.

Standards: ISO 4437/ BS EN 1555

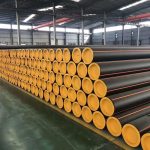

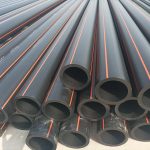

Diameter :16mm-630mm

Pressure Rating : SDR17, SDR11

Certificates: UL, WRAS, NSF, ISO, CE

Length: 5.8 length 20ft , 11.8-12m/L 40ft

Color: Solid Yellow Orange or black with yellow stripes.

Specifations of HDPE Gas Pipe

HDPE gas pipe can be provided from 20mm to 630mm, with specific dimension as below:

| SDR Ratings | SDR11 | SDR17.6 |

| Max. Working PressureFor Natural Gas (Mpa) | 0.4 | 0.2 |

| Norminal Diameterdn (mm) | Wall Thicknesse (mm) | |

| 20 | 2.3 | 2.3 |

| 25 | 2.3 | 2.3 |

| 32 | 3.0 | 2.3 |

| 40 | 3.7 | 2.3 |

| 50 | 4.6 | 2.9 |

| 63 | 5.8 | 3.6 |

| 75 | 6.8 | 4.3 |

| 90 | 8.2 | 5.2 |

| 110 | 10.0 | 6.3 |

| 160 | 14.6 | 9.1 |

| 200 | 18.2 | 11.4 |

| 250 | 22.7 | 14.2 |

| 315 | 28.6 | 17.9 |

| 400 | 36.3 | 22.7 |

| 500 | 45.4 | 28.4 |

| 630 | 57.2 | 35.7 |

Applications of HDPE Gas Pipe

Natural Gas/ Vaporized LPG Conveyance and Distribution

HDPE gas pipes are commonly used for infrastructure systems that deliver natural gas. Because of the characteristics of HDPE pipes,They are providing a safe, reliable, and leak-free means of supplying gas to individual households for purposes like heating, cooking, and hot water generation.

Industrial Gases Distribution

HDPE gas pipes serve businesses such as restaurants, hotels, and industrial plants that require a steady supply of natural gas or LPG. Their flexibility and ease of installation in various terrains and environments make them ideal for urban and rural commercial installations.

Landfill & Leachate Gas Extraction and Conveyance

HDPE pipes are commonly used in LPG and propane gas distribution systems, particularly for residential, commercial, and industrial facilities that rely on liquefied petroleum gas. They provide a safer and more cost-effective alternative to traditional metal pipes in these applications.

Bio Gas and Propane

HDPE gas pipe plays a critical role in gas distribution systems. It has versatility, durability, and cost-effectiveness make it to an ideal for a wide range of applications

Packing and Shipment

- Pipe dia. dn20-63mm can be in coils with 50/100/200/300m length

- pipe dia. dn75-630mm be in bars with 5.8m or 11.8m length

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co.Ltd was established in 2015 and located in High-tech development zone, Luoyang City, covers a large area with state-of-the-art facilities. Our government offers a supportive environment, including convenient transportation and access to essential resources. Since inception in 2015, we have been committed to excellence in pipes and fittings, continuously innovating to meet market demands.

If you need PPR Pipes and Fittings,Please feel free to contact us(sales@pipesandfittings.net)

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

FAQ of HDPE Gas Pipe

1,What does PE100 HDPE gas pipe function?

PE100 Natural Gas Pipes are used for urban gas transmission pipelines, liquefied petroleum gas (LPG) transmission pipelines, and industrial gas pipelines.

PE 100 Pipes have excellent pressure resistance and temperature resistance, ensuring the safety and reliability of the transmission process. In addition, it also has excellent fire resistance, and it is not easy to burn and explode even if it is roasted by open flames, which further ensures the safety of gas transportation. The wall of the PE100 gas pipe is smooth and does not easily accumulate scale, which ensures the patency and cleanliness of the drainage system and effectively solves the problem of drainage pipe maintenance. This type of pipe is also widely used in other industrial fields such as the chemical industry, mining, and marine engineering. It can cope with complex and changing working conditions and environments, and ensure the stable and reliable operation of industrial systems.

2,What do the terms DR and SDR mean?

DR stands for dimension ratio, which is the average outside diameter of a PE pipe divided by its minimum wall thickness. A standard dimension ratio (SDR) is a specific DR based on an ANSI preferred number series. The use of SDRs enables manufacturers to produce pipe to a set of standardized DRs. SDRs include 9, 11, 13.5, 17, 21, 26 and 32.5. All SDRs are DRs, but the converse is not true.

3,How long do HDPE gas pipes last?

HDPE gas pipes have long service life and over 50 years, depending on installation conditions, maintenance, and external factors. Proper installation and environmental conditions can further extend their service life.

4,What is the installation process for HDPE gas pipes?

- Trenching or Boring: A trench is dug or horizontal directional drilling (HDD) is performed for pipe placement.

- Fusion Welding: HDPE pipes are connected through heat fusion, which creates a continuous, leak-free joint.

- Backfilling: After installation, the trench is backfilling with soil to protect the pipes from external damage.

- Connection to the Gas Supply: HDPE pipes are then connected to the gas supply network or building’s internal distribution system.

5. Are HDPE gas pipes environmentally friendly?

Sure, HDPE is an environmentally friendly material,

Recyclable: HDPE pipes are 100% recyclable, reducing environmental impact.

Low Carbon Footprint: HDPE production and installation process requires less energy compared to other materials like metal.

Long Service Time: HDPE pipes have a long service life, which reduces the need for replacements and waste generation over time.

REQUEST A QUOTE

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677