LUOYANG DATANG ENERGY TECH CO.,LTD

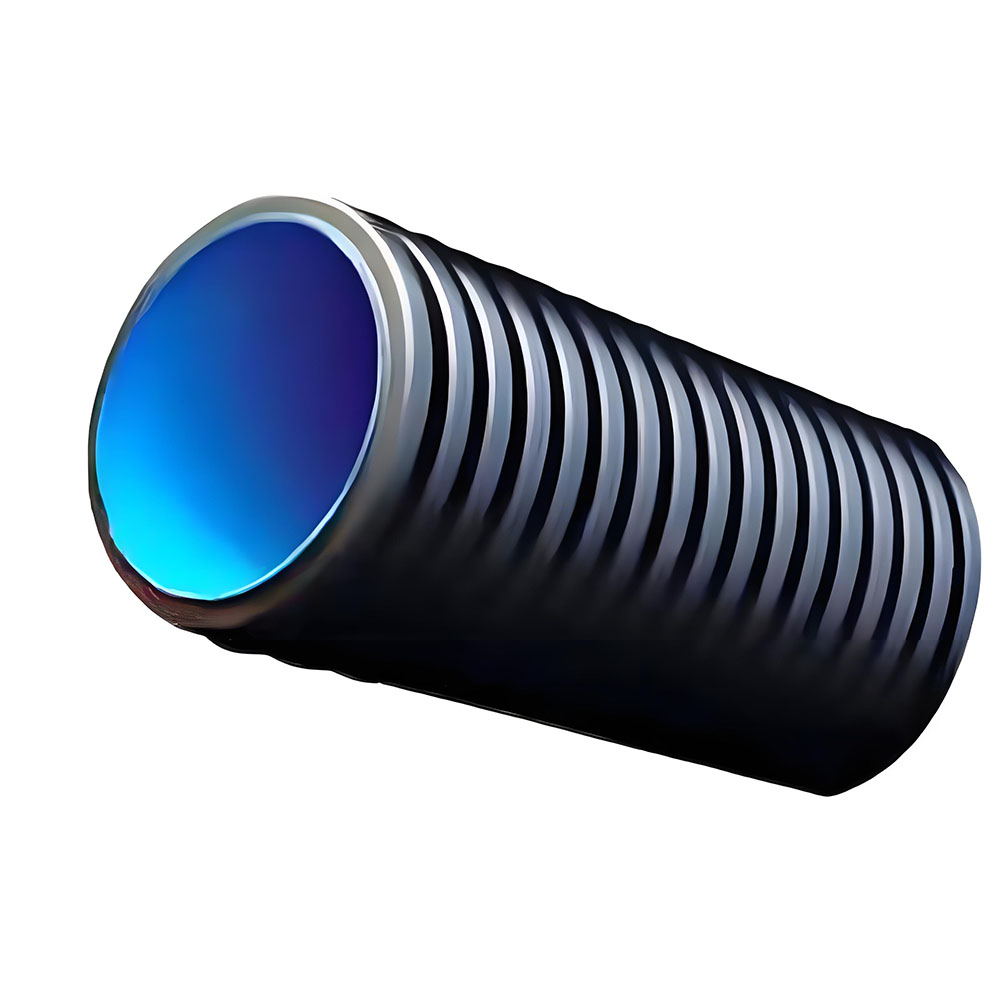

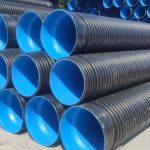

HDPE Double-Wall Corrugated Pipe in Drainage Solutions

PRODUCT PARAMETERS

Description

Introduction of HDPE Double-Wall Corrugated Pipe

HDPE (high density polyethylene) double wall corrugated pipe is a composite structure pipe manufactured by advanced co-extrusion technology, and its unique design includes smooth inner wall and corrugated outer wall. This innovative structure gives it both high strength and flexibility, making it the preferred pipe material for modern municipal engineering, agricultural irrigation, industrial drainage and other fields.

Product structure Features

Double-layer composite structure: the inner wall is smooth (thickness 1.5-3mm) to ensure water flow efficiency, and the outer wall is corrugated (peak height 15-40mm) to enhance the ring stiffness

Material science breakthrough: Using PE100 grade primary high density polyethylene, density ≥0.95g/cm³, melting index 0.3-0.5g/10min

Innovative connection system: double selection of plug and insert electrothermic connection (DN200-DN1200) and clamp connection (DN150 or less)

Details of HDPE Double-Wall Corrugated Pipe

1. Excellent physical properties

Compressive strength: SN8 grade products can withstand a pressure of ≥8000N/m², equivalent to 4 meters of soil cover load

Impact resistance: Impact strength ≥30kJ/m² at 23℃ (ASTM D256 standard)

Flexibility: the bending radius can reach 20-25 times the diameter of the pipe (DN300 pipe minimum bending radius of 6 meters)

2. Long service life

Laboratory accelerated aging tests show that the service life can reach more than 50 years

Uv resistant formula (2.5-3% carbon black masterbatch added) ensures outdoor performance

3. Environmental protection and economic benefits

The weight is only 1/8 of the concrete pipe, reducing the transportation and installation cost by more than 40%

The inner wall friction coefficient is 0.009 (27% lower than the concrete pipe), and the lifting velocity is 15-20%

4. Intelligent installation system

Smart fitting with RFID chip (optional)

Millimeter-level docking accuracy with dedicated welding equipment (output power 4-10kW)

Specifications of HDPE Double-Wall Corrugated Pipe

| Nominal diameter (mm) | Ring stiffness class(kN/m²) | Standard length (m) | Working pressure (MPa) | Applicable temperature range (° C) | Connection method |

| DN200 | SN4/SN8 | 6/9/12 | 0.2-0.6 | – 40 ℃ ~ + 60 ℃ | Electrothermy |

| DN300 | SN8 / SN12.5 | 6/9/12 | 0.2-0.6 | – 40 ℃ ~ + 60 ℃ | Electrothermy |

| DN400 | SN8 / SN12.5 | 6/9/12 | 0.2-0.6 | – 40 ℃ ~ + 60 ℃ | Electrothermy |

| DN500 | SN12.5 / SN16 | 6/9/12 | 0.2-0.6 | – 40 ℃ ~ + 60 ℃ | Electrothermy |

| DN600 | SN12.5 / SN16 | 6/9/12 | 0.2-0.6 | – 40 ℃ ~ + 60 ℃ | Electrothermy |

Technical Parameter

Ring stiffness test standard: ISO 9969

Hydraulic test pressure: 1.5 times the working pressure for 1 hour without leakage

Longitudinal retraction rate: ≤3% (110℃±2℃ environment test)

HDPE Double-Wall Corrugated Pipe Applications

1. Municipal engineering

Urban stormwater management system: can handle a maximum instantaneous flow of Q=5m³/s (DN1200 pipe)

Sewage pipe network: resistant to chemical corrosive environment with pH 2-12

Cable protection sleeve: passed 10kV/1min voltage test

2. Agricultural irrigation

Drip irrigation system: with Φ16mm branch pipe to achieve precision irrigation

Drainage culvert: Slope 0.1-0.3% can achieve artesian drainage

3 Industrial applications

Plant drainage: Through ISO/TR 10358 chemical corrosion resistance certification

Mine drainage: the maximum working pressure can withstand 0.8MPa

4. Special environment

Frozen soil area: -40℃ low temperature impact test without cracks

Coastal areas: through ASTM G154 2000 hours salt spray test

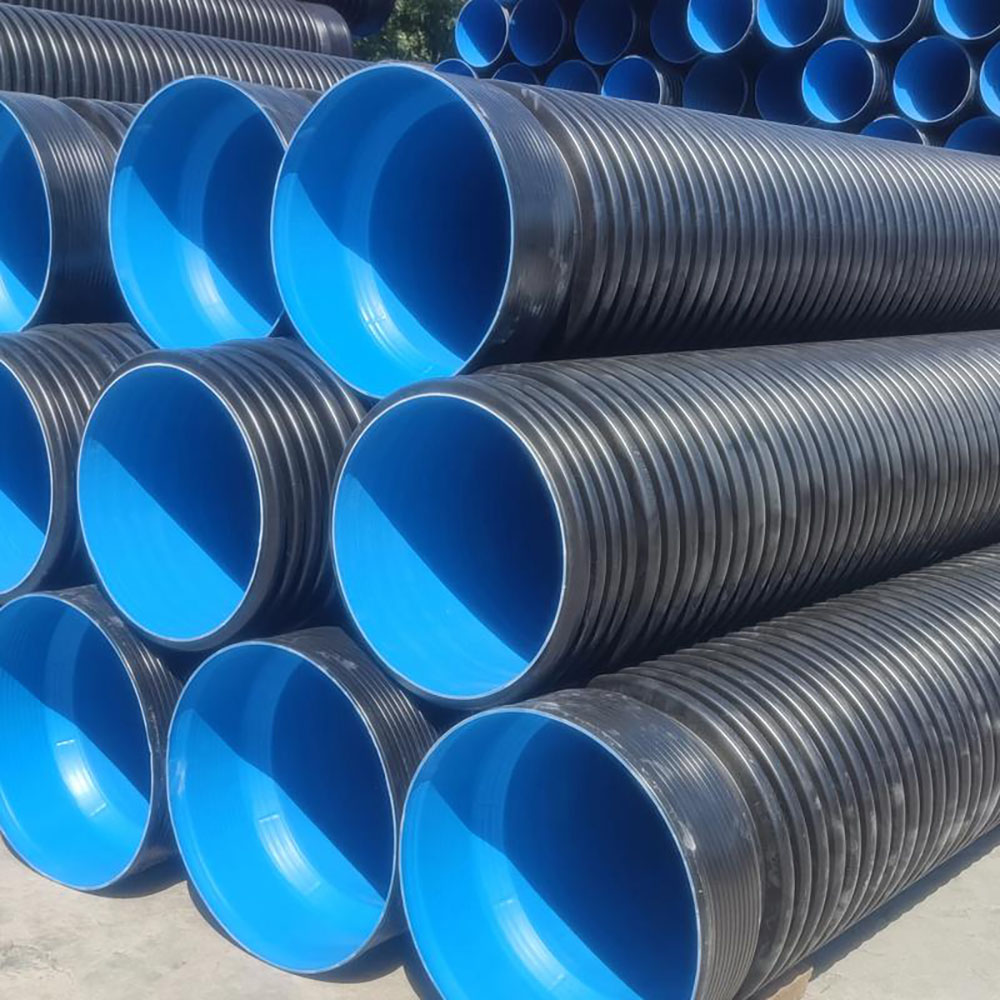

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

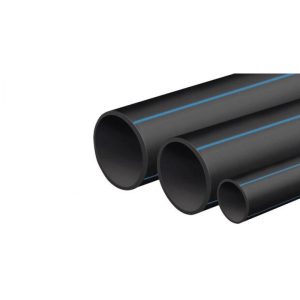

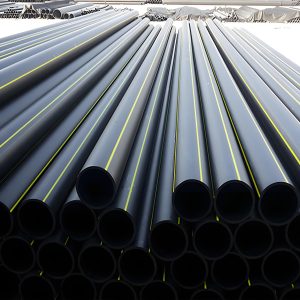

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding our PVC pipe,PE pipe & PPR pipe, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

FAQ of HDPE Double-Wall Corrugated Pipe

Q1: What are the advantages compared with traditional concrete pipe?

The weight is reduced by 87% and the installation efficiency is increased by 3 times

2-3 times longer service life (50 vs 20 years)

More than 35% reduction in integrated engineering costs

Q2: How to ensure the tightness of pipe connections?

Intelligent temperature control system (200-230℃ precise control) is adopted for the electrothermic connection.

Triple sealing guarantee: welding surface + rubber ring + heat shrinkable sleeve

Q3: What is the maximum buried depth of the pipe?

Grade SN8: Recommended burying depth ≤4 meters

Grade SN16: Recommended burying depth ≤8 meters

Special enhanced type can be customized to 12 meters buried depth

Q4: Is trenchless construction supported?

DR17.5 class pipe jacking model is available

Maximum jacking length up to 200 m (DN600 tube)

Q5: How to check the product quality?

Third party test report (SGS/BV, etc.)

Material traceability certificate (PE100 resin batch number)

Factory water pressure test record

REQUEST A QUOTE

RELATED PRODUCTS

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677