LUOYANG DATANG ENERGY TECH CO.,LTD

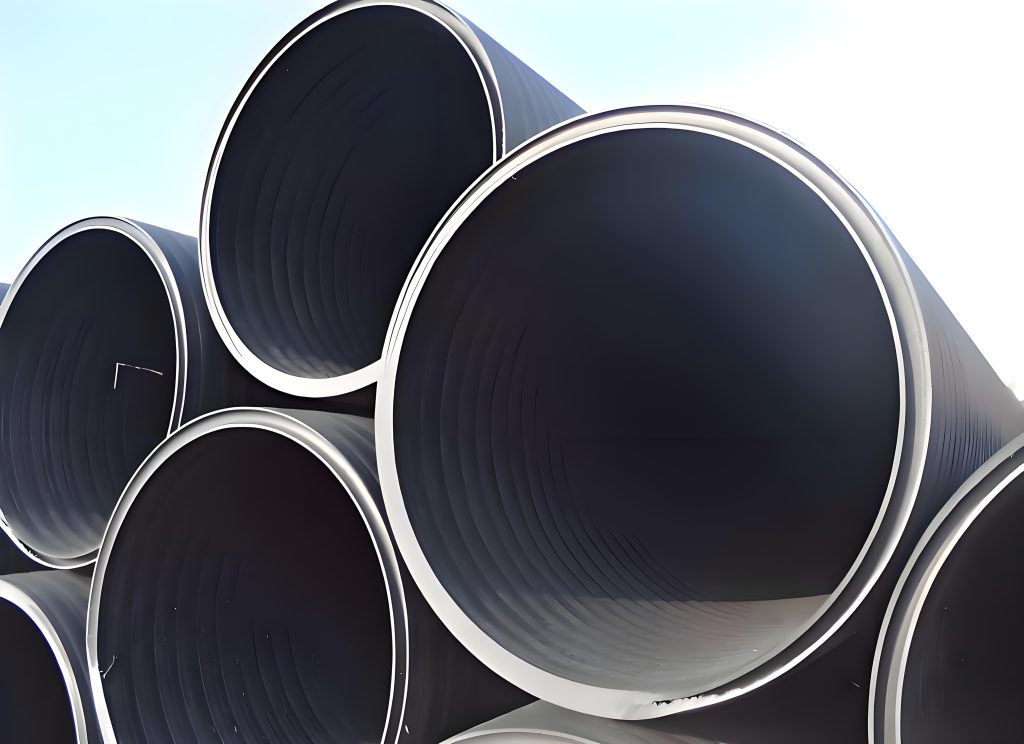

FACTORY DIRECT SUPPLY HDPE DREDGE PIPE

PRODUCT PARAMETERS

Description

Introduction of HDPE Dredge Pipe

HDPE dredge pipe is made of high-density polyethylene at one time. It is non-toxic, odorless, has excellent heat and cold resistance, ultra-high wear resistance and abrasion resistance, as well as superior rigidity and toughness. The HDPE dredge pipes are assembled with flanges at both ends. By using steel bolts and nuts to fix the entire HDPE dredge pipe, it can be easily assembled or disassembled.

Details of HDPE Dredge Pipe

HDPE dredging pipe has been an ideal replacement of steel pipe for dredging works, due to superior performance & characteristic that it has following characteristics:

- Corrosion resistance

- High toughness

- Light weight

- Easy to assemble or dis-mountable

- Excellent flexible and resistance to scratches ability

- Good wear resistance, low wall friction coefficient, small flow resistance, excellent conveying ability

- Low system cost, less maintenance costs, can dramatically reduce the cost for the project

- Long service life

- Recyclable and environment-friendly.

Specifations of HDPE Dredge Pipe

| SDR Ratings | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 |

| Normal Pressure (Mpa) | 0.5 | 0.6 | 0.8 | 1.0 | 12.5 | 16 | 20 |

| Norminal Diameter dn (mm) | Wall Thickness e (mm) | ||||||

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 | 12.3 | |

| 125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 | 14.0 | |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 | |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | |

| 315 | 9.7 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 | 35.2 |

| 355 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 |

| 400 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 |

| 450 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 |

| 500 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 |

| 560 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 |

| 630 | 19.3 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 | 70.3 |

| 710 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 |

| 800 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 |

| 900 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | |

| 1000 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | |

| 1200 | 36.7 | 45.9 | 57.2 | 67.9 | 88.2 | ||

The steel flanges, which are assembled at both ends, can be drilled into EN1092 standard, or customized-made.

Applications of HDPE Dredge Pipe

1, Transport of Dredged Material

HDPE dredging pipes are primarily used to transport the slurry (a mixture of water and dredged sediment) over long distances. They can carry both fine-grained and coarse-grained material, depending on the dredging equipment and the pipe diameter.

2. Efficient Water and Slurry Flow

HDPE pipes are designed to handle high-pressure applications, such as in dredging operations where large amounts of material are moved through the pipe under pressure.

3. Corrosion and Chemical Resistance

Dredging operations often take place in harsh environments, such as seawater or acidic water. The corrosive nature of seawater can cause traditional metal pipes to corrode, leading to maintenance issues and downtime.

4. Flexible Installation

HDPE pipes can be easily bent to follow the contours of the dredging site. This is particularly useful in situations where a fixed pipeline network needs to be established in areas with complex topography or underwater routing.

5. Durability and Longevity

HDPE pipes are resistant to impacts and environmental wear. Their resilience ensures that they perform well even in harsh conditions, such as during transport, installation, and the demanding conditions of dredging operations.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co.Ltd was established in 2015 and located in High-tech development zone, Luoyang City, covers a large area with state-of-the-art facilities. Our government offers a supportive environment, including convenient transportation and access to essential resources. Since inception in 2015, we have been committed to excellence in pipes and fittings, continuously innovating to meet market demands.

If you need PPR Pipes and Fittings,Please feel free to contact us(sales@pipesandfittings.net)

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

FAQ of HDPE water supply pipe

1. What are HDPE dredging pipes?

HDPE dredging pipes are pipes made from High-Density Polyethylene (HDPE), designed specifically for use in dredging operations. They are used to transport water, slurry, or sediment during dredging activities, typically on construction sites, harbors, rivers, and other waterway management projects. HDPE pipes are durable, corrosion-resistant, and flexible, making them ideal for handling abrasive materials and harsh environmental conditions.

2. How do HDPE dredging pipes compare to traditional dredging pipes (such as steel or PVC)?

- Steel Pipes: While steel pipes are strong, they are prone to rust and corrosion, which can lead to a shorter service life in water-based applications. HDPE pipes, on the other hand, are resistant to corrosion and require less maintenance.

- PVC Pipes: PVC pipes are lightweight but not as flexible as HDPE. They are also more prone to cracking under high stress or temperature fluctuations. HDPE provides greater flexibility and toughness.

- HDPE Advantages: HDPE pipes are more durable, flexible, and resistant to wear, which makes them ideal for harsh and abrasive conditions typical of dredging operations.

3. What sizes are available for HDPE dredging pipes?

HDPE dredging pipes come in a wide range of diameters, from small pipes (as small as 2 inches or 50 mm) to very large pipes (up to 120 inches or 3 meters in diameter). Common sizes include:

- Small-diameter pipes: 2″ to 12″ (50 mm to 300 mm)

- Medium-diameter pipes: 12″ to 36″ (300 mm to 900 mm)

- Large-diameter pipes: 36″ and above (900 mm+)

The size of the pipe will depend on the scale of the dredging operation and the volume of material to be transported.

4. Can HDPE dredging pipes be used for both freshwater and seawater dredging?

Yes, HDPE dredging pipes can be used for both freshwater and seawater dredging applications. They are resistant to both freshwater and seawater corrosion, making them versatile for various types of dredging operations.

REQUEST A QUOTE

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677