LUOYANG DATANG ENERGY TECH CO.,LTD

PEX High Temperature Resistant Floor Heating Pipe

PRODUCT PARAMETERS

Description

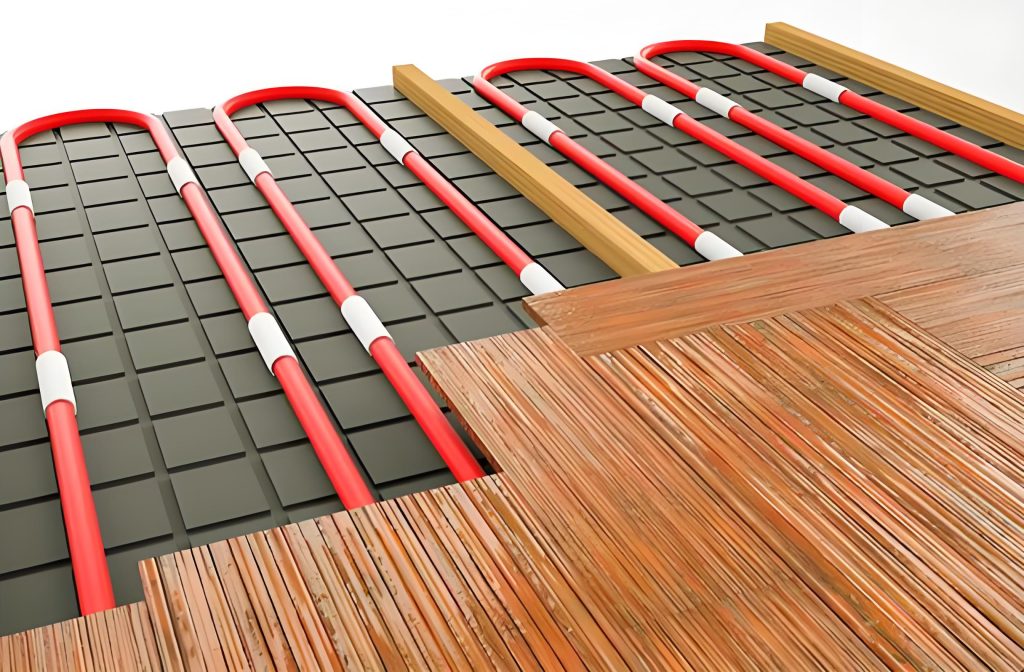

Introduction of PEX Floor Heating Pipe

PEX High Temperature Resistant Floor Heating Pipe is one of the most important material innovations in the field of HVAC in the 21st century. Through the high energy electron irradiation crosslinking process (PEX-A) or silane hydrolytic crosslinking technology (PEX-B).

Details of PEX Floor Heating Pipe

we transform the ordinary polyethylene molecular structure into a three-dimensional network crosslinking system to achieve:

Temperature tolerance: -70℃~110℃ working range

(instant temperature resistance up to 130℃)

Pressure performance: PN10 rated pressure 95℃ hot water long-term operation

Memory effect: Unique shape recovery features to avoid permanent creases

Corrosion resistance: Resistance to acid-base media (pH2-12) and microbial attack

Intergenerational evolution of product technology

| Features | First generation PE-RT | Second generation PEX-B | Third generation PEX-A |

| Degree of crosslinking | no | 65-70% | ≥75% |

| Temperature rating | Class III | Level IV | Level V |

| Coefficient of thermal expansion | 0.18 mm/m ℃ | 0.15 mm/m ℃ | 0.12 mm/m ℃ |

| Burst pressure (95 ° C) | 5.2 MPa | 6.8 MPa | 8.4 MPa |

* Note: Data in this table are based on ISO15875 international standard test environment *

Specifications of PEX Floor Heating Pipe

Standard pipe parameter matrix

| Specification and model | Outside diameter (mm) | Wall thickness (mm) | SDR value | Pressure rating | Length of applicable loop |

| PEX – 16 x 2.0 | 16 | 2.0 | 8.0 | S4 | ≤80m |

| PEX – 20 x 2.3 | 20 | 2.3 | 8.7 | S3.2 | ≤100m |

| PEX-25×2.8(enhanced) | 25 | 2.8 | 8.9 | S2.5 | ≤120m |

SDR (Standard dimension ratio) : The ratio of outer diameter to wall thickness determines the balance of rigidity and flexibility of the pipe

Oxygen permeability: EVOH oxygen blocking layer ≤0.1g/m³·day (DIN4726 standard)

Thermal conductivity: 0.38W/(m·K) (30% better than copper pipe)

Analysis of multi-layer composite structure

Five-layer co-extrusion process:

1. Inner layer: PEX-A antibacterial layer (silver ion coating)

2. Bonding layer: modified polyethylene

3. Oxygen blocking layer: EVOH (ethylene-vinyl alcohol copolymer)

4. Reinforcing layer: glass fiber reinforced PEX

5. Outer layer: anti-UV modified layer

Engineering grade product advantages

Laboratory verification data

Cyclic pressure test: 5000 1.0MPa pressure fluctuations (ENISO10508)

Long-term hydrostatic strength: ≥50 years of life at 95℃/1.0MPa (ASTM F876)

Bending fatigue test: no crack at 10000 bending radius 5D cycles

Intelligent heating solution

mermaid

graph TD

A[heat source system] –> B[PEX diversity collector]

B –> C[PEX main pipe DN32]

C –> D[PEX floor heating coil DN16/20]

D –> E[Intelligent temperature control system]

E –> F[mobile APP remote management]

Applications of PEX Floor Heating Pipe

Civil construction field

Villa floor heating system: It is recommended to use PEX-20×2.3 pipe with a double zigzag cloth pipe with a spacing of 150mm

Apartment hardcover room: PEX-16×2.0 pipe + modular quick assembly system, construction efficiency increased by 40%

Commercial engineering cases

Snow melting system of ice and snow venue: stable operation in -25℃ environment, tube spacing encrypted to 100mm

Agricultural greenhouse heating: pesticide corrosion resistant design, with PE-RT mixed transport system

Special industrial applications

Hangar deicing system: anti-static PEX tube + carbon fiber reinforced layer

Chemical pipeline heat tracing: three-layer oxygen blocking structure +PTFE lining

Global Certification System

Drinking water safety: NSF/ANSI 61, KTW (Germany)

Fire safety certification: BS476 Part6/7 (UK), DIN4102 B1 (Germany)

Environmental certification: Blue Angel (Blue Angel), LEED plus

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co.Ltd was established in 2015 and located in High-tech development zone, Luoyang City, covers a large area with state-of-the-art facilities. Our government offers a supportive environment, including convenient transportation and access to essential resources. Since inception in 2015, we have been committed to excellence in pipes and fittings, continuously innovating to meet market demands.

If you need PPR Pipes and Fittings,Please feel free to contact us(sales@pipesandfittings.net)

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

FAQ of PEX Floor Heating Pipe

Q: How to choose PEX pipe and aluminum-plastic pipe?

A: In the field of radiant heating, all-plastic PEX tubes have better heat transfer efficiency (thermal conductivity 0.38 vs 0.45 W/mK) and lower linear expansion rate (0.035% vs 0.025%/℃).

Q: Floor heating pipe spacing design specification?

A: According to EN1264 standard:

Conventional area: 200mm spacing (pipe diameter 16mm)

Edge area: 150mm encryption area (extending 1.5m to external wall)

Bathroom: 175mm spacing + border insulation tape

REQUEST A QUOTE

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677