LUOYANG DATANG ENERGY TECH CO.,LTD

What Is The Best Pipe To Use For Underground Drainage?

In the underground drainage system of municipal engineering, industrial projects and residential areas, the choice of pipes is very important. In the face of the mainstream PPR pipe, PVC pipe and HDPE pipe in the market, engineers and decision makers need to comprehensively consider multiple factors such as corrosion resistance, high pressure resistance, installation process and economic benefits. Although PPR pipe and PVC pipe can also meet the requirements under certain conditions, HDPE double-wall corrugated pipe with high pressure performance and excellent corrosion resistance, has become an increasingly ideal choice in underground drainage systems.

Part 1, PPR Pipe: The Balance Choice of High Temperature Resistance and Corrosion Resistance

PPR Pipe Characteristics

PPR pipe (random copolymer polypropylene pipe) is known for its high temperature resistance (long-term use temperature 70℃) and chemical corrosion resistance, and its molecular structure is stable, especially suitable for transporting industrial wastewater containing acid and alkali components. Its inner wall smoothness reaches Ra≤0.1μm, which can effectively reduce scale deposition.

PPR Pipe Advantages

Corrosion resistance: Resists pH 2-12 liquids to avoid the risk of metal pipe rust

Hot melt connection: the strength of the welding reaches 90% of the body material, preventing potential leakage

Service life: design life of 50 years, low maintenance cost

PPR Pipe Application Suggestions

Chemical park wastewater discharge system

Ground source heat pump circulating water pipe network

High temperature steam condensate recovery pipeline

PPR Pipe Analysis

The impact strength is only 20kJ/m² (23 ° C), and the heavy duty vehicle rolling area should be avoided Linear expansion coefficient 0.15mm/(m·K), need to set expansion joint compensation

Part 2, PVC Pipe For Drainage System: Cost-effective Choice

Analysis Of PVC U Pipe Performance Parameter

PVC-U Pipe (hard polyvinyl chloride pipe) with 0.6-1.6MPa ring stiffness and a cost advantage of 3-8$ per meter, occupy 60% share of the global underground drainage system. Its Vica softening point is ≥79℃, which can meet the requirements of conventional drainage temperature.

PVC U Pipe Advantage

Cost-effective: Cost of PVC U pipe raw material is 30%-40% lower than HDPE

Convenient construction: No professional equipment is required for socket connection, and the installation efficiency is increased by 50%

Biological Erosion Resistance: Not decomposed by microorganisms, suitable for sewage environment

PVC U Pipe Application

Residential rainwater collection network

Municipal road side ditch drainage system

Low corrosive industrial wastewater discharge

PVC U Pipe Using Tips

Low temperature impact resistance is poor (embrittlement temperature -5℃), the northern region needs to add a toughening agent

Long-term use temperature does not exceed 45 ° C, avoid conveying high temperature media

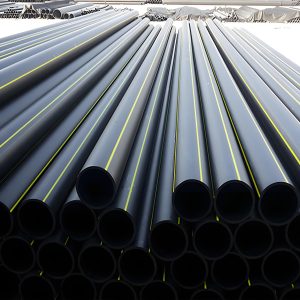

Part 3, HDPE Pipe: A Technical Model of High Pressure Resistance And Flexibility

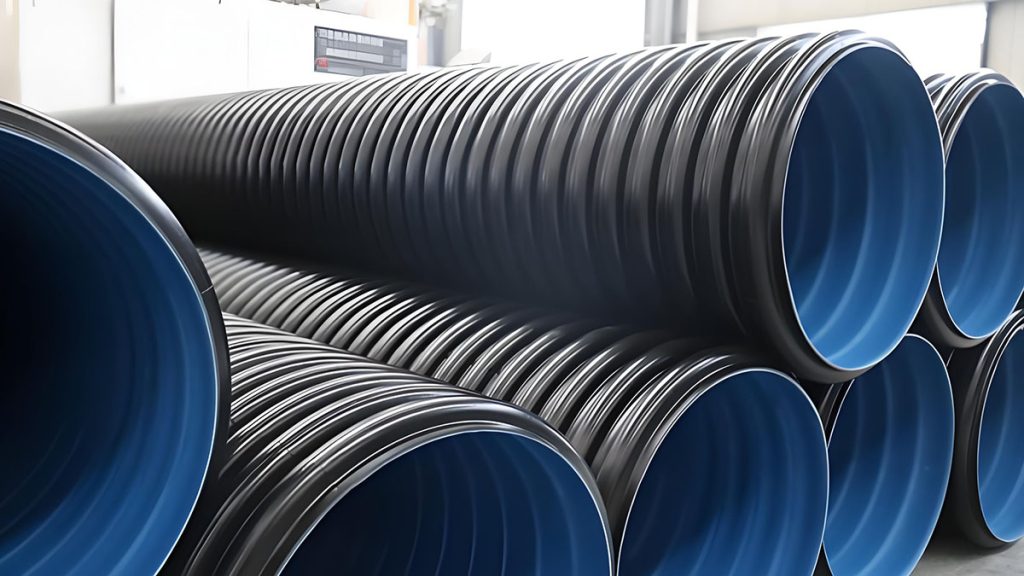

The ring stiffness of HDPE double-wall corrugated pipe can reach SN8 level (8kN/m²), and the elastic bending rate of 1:100 has become the first choice for earthquake zones and settling areas. Its elongation at break exceeds 350% and can withstand 3% of foundation deformation.

HDPE double-wall corrugated pipe characters

High pressure resistance: HDPE pipe has a very high pressure resistance, and can effectively resist external loads under underground stress conditions to ensure long-term stable operation. This is also one of the important reasons for choosing high pressure drainage pipes.

Corrosion resistance: HDPE material itself has strong chemical resistance and corrosion resistance, whether it is industrial wastewater or urban sewage, HDPE pipe can maintain stable performance and become the ideal choice for corrosion resistant sewage pipes.

Light weight and easy to installation: HDPE pipe is light in weight, more convenient for transportation and installation, and its flexible design makes it easier to adapt to terrain changes in the design specification of underground pipe network, reducing the risk caused by foundation settlement.

Long service life: Because HDPE pipe is not susceptible to corrosion and aging, its service life can usually reach more than 50 years, in line with international drainage pipe standards, to ensure the maximum return on investment.

HDPE double-wall corrugated pipe advantage

Zero leakage connection: electric fusion connection to achieve molecular level fusion

Wear resistance: the wear coefficient is 4 times that of the steel pipe, suitable for the medium containing gravel

Eco-friendly: 100% recyclable, in line with green building standards

HDPE double-wall corrugated pipe applications

Highway integrated pipe corridor drainage

Landfill leachate collection system

Coastal saline drainage works

HDPE double-wall corrugated pipe cost

The use of winding structural wall pipe (HDPE-SSP) can reduce the material consumption by 15%

The life cycle cost is 40% lower than that of concrete pipe

Part 4,Comparison of HDPE Pipe,PVC Pipe & PPR Pipe

| Index | PPR Pipes | PVC pipes | HDPE pipes |

| Compressive strength (MPa) | 1.0-1.6 | 0.6-1.2 | 2.5-4.0 |

| Temperature range (° C) | – 20 ~ 95 | – 5 ~ 60 | – 50 ~ 80 |

| Connection method | Hot melt butt joint | Adhesive/rubber ring | Electromelt/heat shrink tape |

| Cost per kilometer (10,000 USD) | 18-25 | 10-15 | 30-45 |

| Applicable pipe diameter (mm) | 20-160 | 110-630 | 200-3000 |

Part 5,How To Choose The Correct Pipes

1. Geological conditions are preferred:

Earthquake zone/soft ground → Select HDPE pipe

Stable rock formation → Consider PVC pipe to reduce costs

2. Medium characteristics orientation:

Oil/high temperature wastewater → PPR pipe

Containing solid particles → HDPE double-wall bellows

3. Budget constraint considerations:

Short-term project → PVC pipe

Centennial Project → HDPE pipe

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PVC Pipe,PPR Pipe & HDPE Pipe , please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net