LUOYANG DATANG ENERGY TECH CO.,LTD

Understanding PPR Pipe Specification

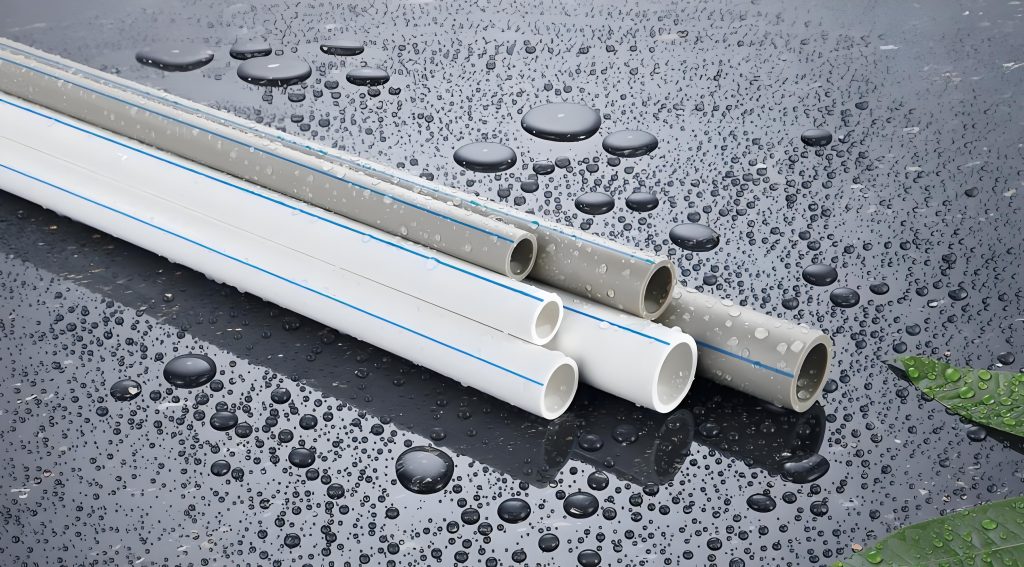

I. Introduction of PPR water pipe

PPR (random copolymerized polypropylene) pipe is a new type of environmentally friendly plastic pipe, with its high temperature resistance, corrosion resistance, long life (more than 50 years) and other characteristics, widely used in construction of hot and cold water systems, HVAC engineering and industrial fluid transportation field. Its core advantages include:

Safety and environmental protection: Non-toxic and odorless, in line with drinking water health standards (GB/T 17219).

Strong temperature resistance: Long-term use temperature of 70°C, short-term temperature resistance up to 95°C.

Pressure and corrosion resistance: No electrochemical corrosion problems, suitable for acid and alkali environments.

Convenient installation: Hot melt connection technology to achieve seamless sealing, to eliminate the risk of leakage.

2, the specifications of PPR water pipe parameters

1. Outside diameter and wall thickness

PPR pipe specifications to the nominal outside diameter (dn), common sizes include:

dn20 (4-minute pipe), dn25 (6-minute pipe), dn32 (1-inch pipe), dn40, dn50, dn63 and so on.

The wall thickness (en) is calculated based on the SDR value and directly affects the pressure capacity (see SDR details below).

2. Pressure rating (PN value)

PPR pipes are divided into four classes according to nominal pressure:

| PN value | Applicable scenes | Maximum working temperature |

| PN10 | Cold water system (≤20°C) | 60°C (short-term) |

| PN16 | Conventional hot and cold water system | 70°C (long-term) |

| PN20 | High temperature heating system | 80°C (long-term) |

| PN25 | Industrial high pressure systems | 95°C (short term) |

3. SDR (Standard Dimension Ratio)

SDR (Standard Dimension Ratio) is the core design parameter of PPR pipe, defined as the ratio of pipe outer diameter (dn) to wall thickness (en):

SDR = outer diameter (dn) / wall thickness (en)

SDR value is smaller → thicker wall → the stronger the pressure-bearing capacity, suitable for high-pressure systems.

The larger the SDR value → the thinner the pipe wall → better economy, suitable for low-pressure scenarios.

Common SDR values and corresponding pressure ratings

| SDR | Nominal Pressure (PN) | Applicable Scenarios |

| 6 | PN25 | Industrial high pressure, high temperature steam |

| 7.4 | PN20 | Centralized heating, high temperature water circulation |

| 9 | PN16 | Conventional hot and cold water systems |

| 11 | PN10 | Low-pressure cold water transportation |

3. How to select according to SDR?

1. Selection according to system pressure demand

High-pressure scenario (e.g. HVAC boiler room): choose SDR6 or SDR7.4 with large wall thickness and strong creep resistance.

Conventional residential hot and cold water: SDR9 (PN16) can meet more than 90% of the demand.

Low-cost cold water project: SDR11 (PN10) has the best economy.

2. Matching by temperature adaptability

High temperature system (≥70°C): low SDR value (e.g. SDR7.4) must be selected to avoid deformation due to thermal expansion.

Low temperature chilled water system: High SDR value (e.g. SDR11) can be selected to reduce cost.

3. Reference to industry standards

National standard GB/T 18742: clear PPR pipe SDR series and size tolerance requirements.

ISO 15874: international general standard, applicable to export-oriented projects.

4, PPR water pipe installation precautions

Thermal fusion temperature control: 260 ± 5 ° C for the optimal fusion temperature, to avoid too high leading to carbonization of the material.

Socket depth: need to match the specifications of the pipe fittings (such as dn20 pipe insertion depth of 14mm).

Pressure test: 1.5 times the working pressure holding pressure test (≥ 30 minutes) after installation.

PPR water pipe through the scientific design of the SDR parameter system, to achieve a balance between performance and cost. When selecting the type, you need to integrate the three elements of system pressure, temperature and budget, and prioritize the selection of high-quality raw materials in line with the national standard (such as Scandinavian Chemical RA130E) products. As a professional manufacturer, we offer a full range of SDR-specification PPR pipes and customized solutions to help customers build safe and durable piping systems.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a professional manufacturer and supplier of pipes and fittings. We offer PPR pipes, PVC pipes, PE pipes, and floor heating pipes and fittings for all types of pipes, with high quality and competitive prices. If you have any inquiries about pipes and fittings, please do not hesitate to contact us. You can click on the product to get in touch with us.