LUOYANG DATANG ENERGY TECH CO.,LTD

PVC Pipe vs. HDPE Pipe: Which is better?

In water supply and drainage, gas transmission, agricultural irrigation and other projects, PVC (polyvinyl chloride) Pipeline and HDPE (high-density polyethylene) Pipeline are the two most commonly used plastic pipes. However, there are significant differences between the two in performance, cost and application scenarios. This article will be from the material characteristics, construction requirements, economy, environmental protection four dimensions of a comprehensive comparison, and attached to the real project selection cases, to help you find the best solution.

1. Comparison of basic material characteristics: rigidity VS flexibility

1). PVC pipe characteristics

High rigid strength: bending modulus ≥2,400MPa, suitable for scenes requiring structural stability (such as building risers);

Chemical corrosion resistance: resistant to acid and alkali, salt spray, grease, widely used in chemical wastewater treatment;

Temperature range: -10℃~60℃ (special formula can be extended to -30℃~90℃);

Flame retardant: self-extinguishing from fire, in line with UL94 V-0 fire standard.

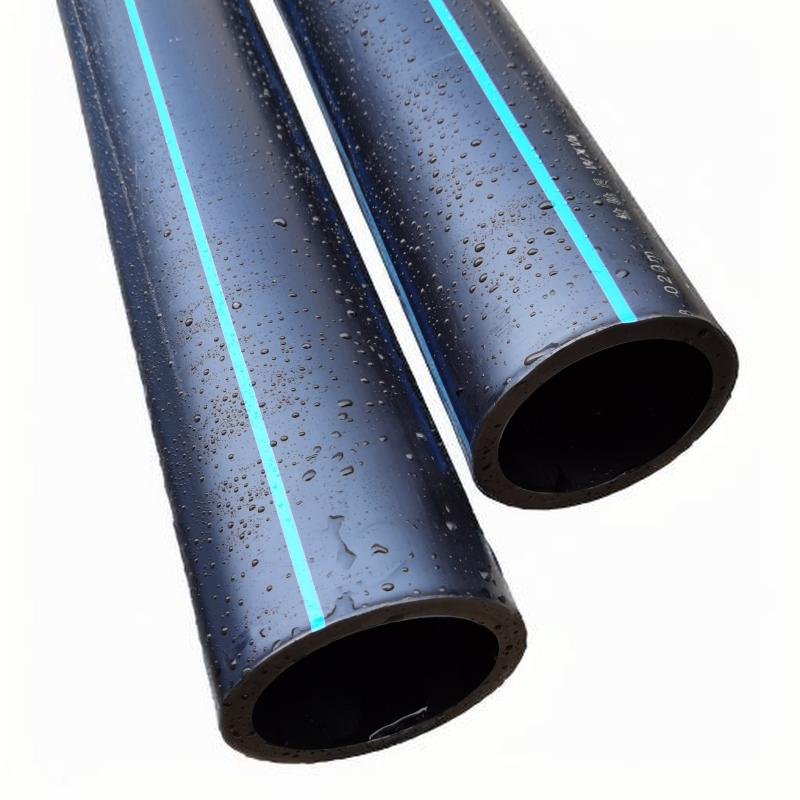

2). HDPE pipeline characteristics

High flexibility: the bending radius can reach 20 times the diameter of the pipe, suitable for trenchless laying (such as pipe jacking construction);

Low temperature resistance: -60℃ is still elastic, suitable for gas transmission in cold areas;

Impact resistance: notched impact strength ≥30kJ/m², strong earthquake deformation resistance;

Slow crack growth resistance: life forecast more than 50 years (ASTM D2837 standard).

Scientific Conclusion:

Choose PVC: scenes that require rigid support, corrosion resistance, and fire protection (such as building drainage, industrial pipes);

Choose HDPE: need flexible pressure resistance, low temperature resistance, long distance laying of the scene (such as gas pipeline, submarine cable sheath).

2. Comparison of construction and installation costs

| Project | PVC Pipeline | HDPE Pipeline |

| Connection method | Adhesive/flange/thread | Hot melt butt/electric melt connection |

| Installation speed | Fast (no professional equipment required) | Slow (hot melt machine, technical training required) |

| Labor cost | Low (can be operated by ordinary workers) | High (a licensed welder is required) |

| Repair difficulty | Easy (partial replacement) | Difficult (requires cutting and remelting) |

Comparison of cases:

Municipal water supply project (10km DN200 pipeline) :

Total cost of PVC: material fee $1.8 million + installation fee $500,000 = $2.3 million;

HDPE total cost: material cost $2.4 million + installation cost $1.2 million = $3.6 million;

PVC saves 36% of the cost and shortens the construction period by 25 days.

3. Economic analysis of the whole life cycle

1. Initial investment

PVC price is usually 15%~30% lower than HDPE (DN100 pipe as an example: PVC≈$30/m, HDPE≈$40/m);

Exception scenario: HDPE can save road surface repair costs in trenchless projects, and the comprehensive cost may be lower.

2. Maintenance costs

PVC: almost maintenance-free (corrosion resistance, no scaling);

HDPE: the hot melt quality of the joint affects the reliability of the system and needs to be tested regularly (especially for gas projects).

3. Energy saving efficiency

PVC inner wall smoothness (roughness coefficient 0.009) is better than HDPE (0.011), fluid resistance is reduced by 18%, long-term pumping energy consumption is lower.

4. Environmental protection and sustainability dispute

1. Recyclability

PVC: can be physically recycled into floors, soles, etc., but need to be sorted and cleaned (complex chlorine treatment);

HDPE: the recycling process is more mature, and the recycled material is widely used in packaging bottles and pipes (closed-loop recovery rate can reach 95%).

2. Production energy consumption

PVC production energy consumption: about 18MJ/kg (mainly from chlor-alkali process);

HDPE production energy consumption: about 25MJ/kg (crude oil cracking to ethylene);

Conclusion: PVC has about 28% lower carbon emissions than HDPE (source: Plastics Europe).

3 Health controversy

PVC: the raw material contains chlorine, but the finished pipe is non-toxic after NSF/ANSI 61 certification (need to choose a regular brand);

HDPE: no chlorine, no plasticizers, food grade applications are preferred (such as direct drinking water pipes).

5. Actual combat Selection guide: 5 common scenarios are recommended

Scene 1: Urban underground drainage network

PVC is recommended: rigid support avoids soil settlement and deformation, is resistant to sewage corrosion, and has the best comprehensive cost.

Avoid pit tips: Avoid using thin-walled PVC in areas where heavy vehicles frequently roll.

Scenario 2: Natural gas delivery line

Forced use of HDPE: flexibility to adapt to foundation deformation, low temperature resistance and anti-brittleness (GB 15558.1).

Scenario 3: Agricultural drip irrigation system

Recommended PVC: PVC (low cost, UV resistance) for the main pipe, HDPE (flexible and easy to lay) for the branch pipe.

Scenario 4: Waste water pipe in chemical park

Priority PVC: Acid and alkali resistance is better than HDPE (HDPE is easy to swell under concentrated sulfuric acid environment).

Scenario 5: Home decoration water supply pipe

The southern region chooses PVC: cost-effective, convenient construction;

Northern heating pipe selection HDPE: high temperature resistance (80℃) performance is more stable.

The ultimate comparison table:

| Metrics | PVC | HDPE |

| Maximum temperature resistance | 60 ° C (90 ° C for short term) | 80 ° C (short-term 110 ° C) |

| Minimum bending radius | 10 times pipe diameter | 20x pipe diameter |

| Uv resistance | Excellent (with stabilizer) | Poor (add carbon black) |

| Typical application | Building drainage/chemical piping | Gas/underfloor heating/slurry delivery |

| 50-year combined cost | Low $ | $mid-high |

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a professional manufacturer and supplier of pipes and fittings. We offer PPR pipes, PVC pipes, PE pipes, and floor heating pipes and fittings for all types of pipes, with high quality and competitive prices. If you have any inquiries about pipes and fittings, please do not hesitate to contact us. You can click on the product to get in touch with us.