LUOYANG DATANG ENERGY TECH CO.,LTD

Practical Exploration of Ensuring PE Pipe Quality & Extending Service Life

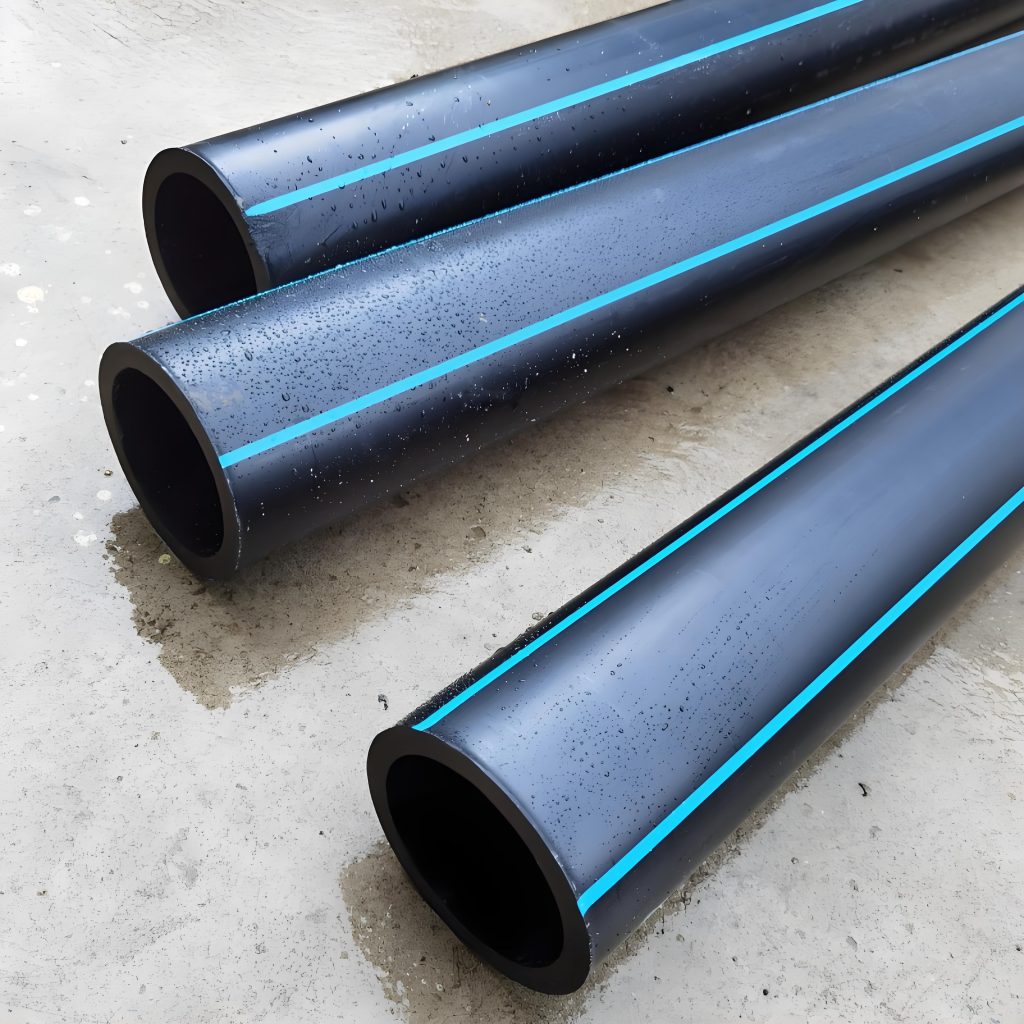

In today’s industrial and civil pipeline engineering, PE pipe has become the first choice for many engineering projects because of its anti-corrosion, pressure resistance, convenient construction and other advantages. However, the service life of PE pipe is affected by many factors, such as raw materials, production process, construction method and environmental conditions. In order to ensure the quality and service life of PE pipes, we have invested a lot of energy and resources in the selection of raw materials, production process control, construction management and environmental adaptability.

First, Strictly Select High Quality Raw Materials

As the first line of defense for PE pipe production, the quality of raw materials directly determines the anti-aging performance of the pipe. We know that the domestic top PE raw materials can reach 50 years in anti-aging, but in the actual production process, due to the diversity of customer needs, it is impossible to use all the national standard PE material. To this end, we have established a long-term and stable cooperative relationship with well-known raw material suppliers at home and abroad, and strictly monitor the index data of each batch of raw materials.

we not only conduct a comprehensive test on the chemical composition of raw materials, molecular weight distribution and other parameters, but also establish a raw material traceability system to ensure that each batch of raw materials meet the standards, and even exceed the national standard requirements in some links, to provide a solid guarantee for the follow-up pipe performance.

Second, Optimize The Production Process, Strict Control of Product Quality

The production process is an important link to determine the pressure bearing capacity and service life of PE pipes. Some bad manufacturers may cut corners in order to reduce costs, such as wall thickness deviation beyond the standard or poor mechanical equipment condition, resulting in excessive internal impurities in the pipe, seriously affecting product performance. We attach great importance to this and have taken the following measures:

Equipment upgrade and maintenance: We introduce international advanced production equipment to ensure the high precision and stability of mechanical equipment, and reduce the production error caused by equipment failure or aging.

Strict process control: Through automatic monitoring of the entire production process, real-time detection of wall thickness, inner and outer diameter, material uniformity and other indicators, to ensure that products can meet or exceed the design requirements at each stage.

Quality sampling system: A strict quality sampling system has been established, from raw materials to finished products for the whole chain testing to ensure that each PE pipe meets the standard requirements, and truly achieve “0 defects”.

Third, Standardize Construction Management to Prevent Pipe Damage

In the construction process of PE pipe, due to improper installation and operation or friction, collision and other problems in the transport link, it may cause physical damage to the pipe itself, and thus reduce the service life. To this end, we have also done fine management in the construction link:

Before construction training: In order to ensure that the construction team has the correct operation method, we regularly conduct professional training for the construction personnel to explain the characteristics and precautions of PE pipes.

Site monitoring and management: At the construction site, we have arranged professional and technical personnel to monitor the entire construction process, timely discover and correct non-standard operations, and prevent the pipe from scratch, bending and other problems during installation.

Transportation and packaging optimization: In view of the pipe damage that may be caused by long-distance transportation, we use special transportation tools and high standards of packaging materials to ensure that the pipe remains in good condition during transportation.

Fourth, Adapt to The Changing Environment, Improve The Durability of The Pipe

Although PE pipe has anti-corrosion performance, it will still have performance degradation in extreme environments (such as strong acid and alkali, high temperature greater than 60° or long-term freezing conditions). To this end, we continue to optimize in product development and application:

Environmental adaptability test: For different application scenarios, we have carried out a series of environmental adaptability tests, including high temperature, low temperature, chemical medium immersion and other tests, in order to adjust the formula and process parameters according to the test results.

Product diversification design: In order to meet different engineering needs, we have launched a series of PE pipe products. For example, for high temperature environment, we have developed special high temperature resistant PE pipe; In cold areas, we have a series of pipes adapted to low temperature changes.

Technological innovation and upgrading: Constantly introduce new technologies and new materials to improve the overall performance of PE pipes and extend their service life. For example, by improving the ratio of additives, the anti-aging and chemical resistance of the pipe is further improved.

Fifth, Future Outlook and Continuous Improvement

We always believe that only by constantly pursuing excellence can we remain invincible in the fierce market competition. In the future, we will continue to make efforts in the following aspects:

Strengthen research and development investment: Increase research and development investment, and cooperate with well-known scientific research institutions and enterprises at home and abroad to further improve the performance and quality of PE pipes.

Improve the whole life cycle management: From design, production to construction, post-maintenance, build the whole life cycle management system to ensure that the product can play the best performance in the whole use process.

User feedback and market research: Actively collect user feedback, regularly carry out market research, and constantly improve product design and process to meet the individual needs of different users.

The quality and service life of PE pipeline is not only determined by a single factor, but a systematic engineering involving raw materials, production process, construction management and environmental adaptability. Through strict selection of high quality raw materials, optimization of production process, standardized construction management and continuous technological innovation, we provide customers with high quality PE pipes with high aging resistance, pressure resistance and environmental adaptability. In the future development, we will continue to take the user as the center, relying on scientific and technological innovation and the whole process quality management, and set a higher standard and benchmark for the PE pipe industry.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding Industrial-grade PE100 Pipes , please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net