LUOYANG DATANG ENERGY TECH CO.,LTD

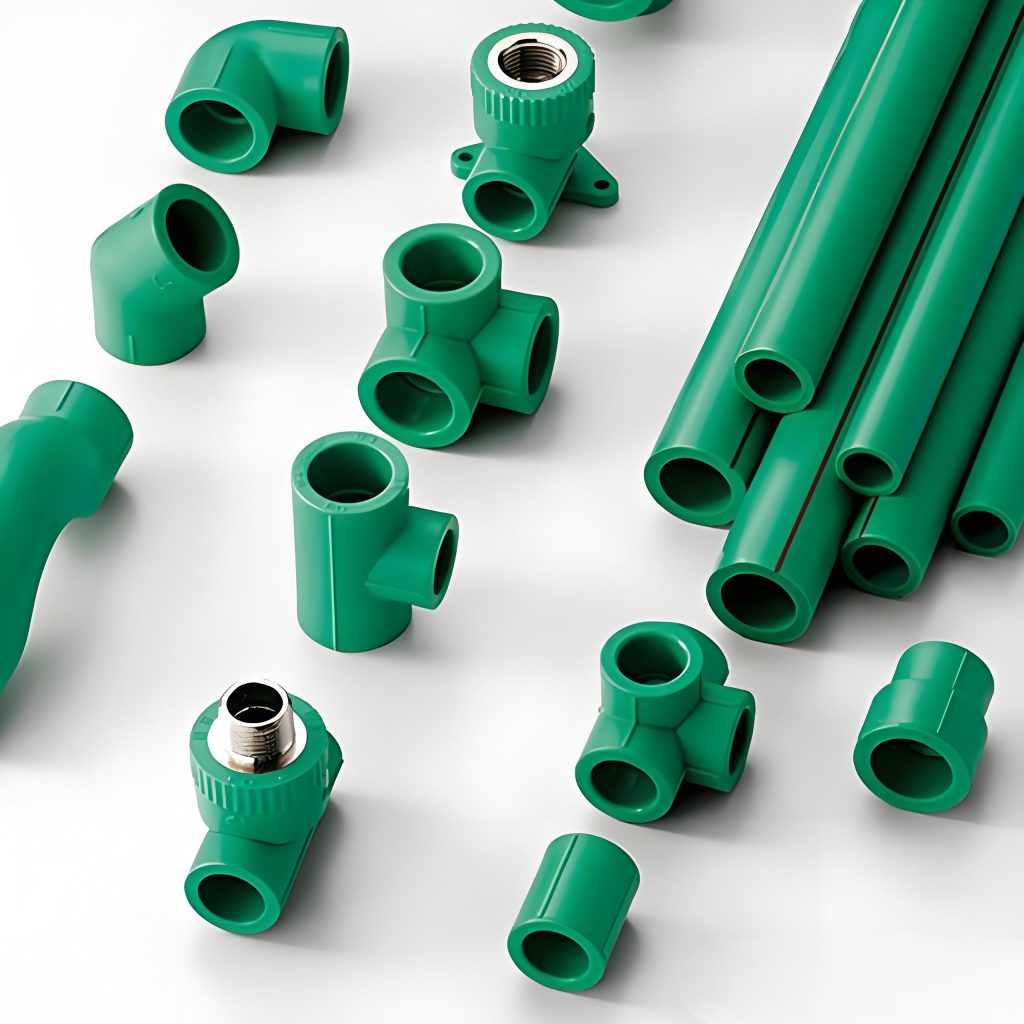

PPR Pipes: Innovative Solutions for Modern Plumbing Systems

In the field of construction and engineering, the choice of piping system directly affects the quality, cost and service life of the project. With the rapid development of materials science, PPR (random copolymer polypropylene) pipe has become the mainstream choice of global HVAC, water supply and drainage system with its excellent performance. As a professional supplier of pipe and accessories export, we are committed to providing customers with technology-leading solutions. We invite our global partners to explore the infinite possibilities of PPR technology — whether it is a commercial complex, an industrial plant or a municipal project. Let us build safe, economical and durable fluid transport systems with innovative materials.

First, Materials Science: The genetic advantages of PPR pipes

The core material of PPR pipeline is the third generation modified polypropylene, which combines propylene monomer with ethylene monomer through random copolymerization technology to form a unique molecular structure. The innovative design of this material gives PPR three inherent advantages:

1. Molecular stability breakthrough

The crystallinity of PPR is 30% lower than that of ordinary PP materials, and the molecular chain is arranged more evenly, so that it can still maintain excellent creep resistance at high temperatures. Experimental data show that the service life of PPR pipe under 70℃ and 1MPa pressure can reach more than 50 years, far exceeding the traditional plastic pipe such as PVC and PE.

2. Chemical inertness revolution

Polypropylene materials are naturally resistant to acid and alkali corrosion, and can remain structurally intact in extreme environments with a pH of 2-12. In contrast to the defects of copper pipe which is prone to sulfide corrosion and galvanized steel pipe which is easy to rust, PPR pipe can completely eliminate the risk of leakage caused by corrosion.

3. Food grade safety guarantee

PPR raw materials that have passed international certifications such as FDA, NSF and WRAS are completely free of heavy metals and plasticizers, and will not produce secondary pollution when transported to drinking water. The German KTW standard test shows that the total number of bacterial colonies on the inner wall of PPR pipe after long-term use is only 1/5 of that of copper pipe.

Second, physical properties: redefine the pipeline engineering standards

In a real-world engineering environment, PPR pipes exhibit amazing physical properties:

1. Perfect carriers for thermal systems

Operating temperature range: -20℃ to 95℃ (instant peak up to 110℃)

Thermal conductivity is only 0.24W/m·K, 200 times lower than metal pipes, effectively reducing heat loss

The coefficient of thermal expansion is 1.5×10⁻⁴/℃. The influence of deformation can be completely eliminated with U-shaped compensator

2. Fluid dynamics optimization design

Inner wall smoothness Ra≤0.007mm, friction resistance coefficient is only 60% of the steel pipe

Under the same flow rate, PPR pipe diameter is reduced by 1-2 grades compared with metal pipe, saving 20% installation space

3. Mechanical performance of seismic and compressive resistance

Longitudinal retraction rate < 2%, tensile strength ≥27MPa

Through the ISO 1167 standard test, the bursting pressure can reach 6MPa (3 times the conventional working pressure)

Third, Installation revolution: The disruptive innovation of hot melt connection technology

The threaded connection and flange connection of traditional pipelines have high leakage rate and low construction efficiency. PPR pipeline adopts innovative hot melt socket technology, which brings four major changes:

1. Zero leakage sealing system

Through the accurate temperature control of 260 ° C ±10 ° C, the pipe and pipe fittings melt into molecular level combination, forming a completely homogeneous connection interface. According to EN 12201 standard test, the strength of the hot melt joint reaches more than 90% of the pipe body.

2. The construction efficiency is improved exponentially

A single DN20 joint takes only 8 seconds to weld

It is 5 times faster than galvanized steel pipe installation, and the comprehensive labor cost is reduced by 40%

3. Maintenance free design philosophy

The connection mode of integrated molding does not need sealant, raw material belt and other consumables, which fundamentally eliminates the leakage risk caused by the aging of sealing materials.

4. All-terrain adaptability

Special formula of PPR raw materials can be normal construction in -5℃ environment, with portable hot melt machine, suitable for basement, high altitude and other complex working environment.

Fourth, the whole life cycle cost: visible economic advantages

From a project lifecycle perspective, PPR pipelines show amazing cost control capabilities:

Initial investment comparison (take DN25 pipeline system as an example)

| Type of material | Pipe cost | Cost of fittings | Installation hours | Combined cost |

| Galvanized steel pipe | $1.2 / m | $0.8/ piece | 3h/10m | $28/m |

| Copper tube | $4.5 / m | $3.2/ piece | 2.5 h / 10 m | $62/m |

| PPR tube | $1.8 / m | $1.2/ piece | 0.5 h / 10 m | $14/m |

Operating and maintenance costs

Annual leakage rate < 0.05%, which is 90% lower than the maintenance cost of metal piping system

50 years free replacement design, to avoid the loss of business interruption caused by periodic renovation

Fifth, Green Gene: Engineering practice for sustainable development

The PPR pipeline perfectly fits the global low-carbon development strategy:

1. Production process: the energy consumption of tons of products is only 1/8 of the steel pipe, and the CO₂ emissions are reduced by 85%

2. Transportation stage: density 0.91g/cm³, the same container load increased by 30%

3. Recycling: 100% recycling can be achieved through the crushing and granulation process, which is certified by UL Ecologo

Sixth, Application scenarios: from residential to industrial coverage of the whole field

Civil field: central heating, floor heating system, cold and hot water supply

Commercial buildings: central air-conditioning condensate system, fire sprinkler pipe network

Industrial scene: chemical medium transportation, food grade pipeline, compressed air pipeline

Agricultural innovation: water-saving irrigation, soilless cultivation nutrient solution circulation

| Industry | Use Cases | Key Advantage |

| Residential Plumbing | Hot water distribution, underfloor heating | Leak-free fusion joints |

| Industrial Systems | Chemical transport, compressed air lines | Corrosion-resistant PN20 rating |

| Commercial HVAC | Solar thermal loops, chilled water systems | AS/NZS 4129-compliant fire safety |

Seven, Why Choose Us?

1. The whole system certification guarantee: through ISO 9001, ISO 14001, CE, WaterMark and other 23 international certifications

2. Customized solutions: Provide full-size product lines from DN20 to DN160, support ODM color/logo customization

3. Global service network: set up bonded warehouses in 12 countries, 72-hour emergency response mechanism

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a professional manufacturer and supplier of pipes and fittings. We offer PPR pipes, PVC pipes, PE pipes, and floor heating pipes and fittings for all types of pipes, with high quality and competitive prices. If you have any inquiries about pipes and fittings, please do not hesitate to contact us. You can click on the product to get in touch with us.