LUOYANG DATANG ENERGY TECH CO.,LTD

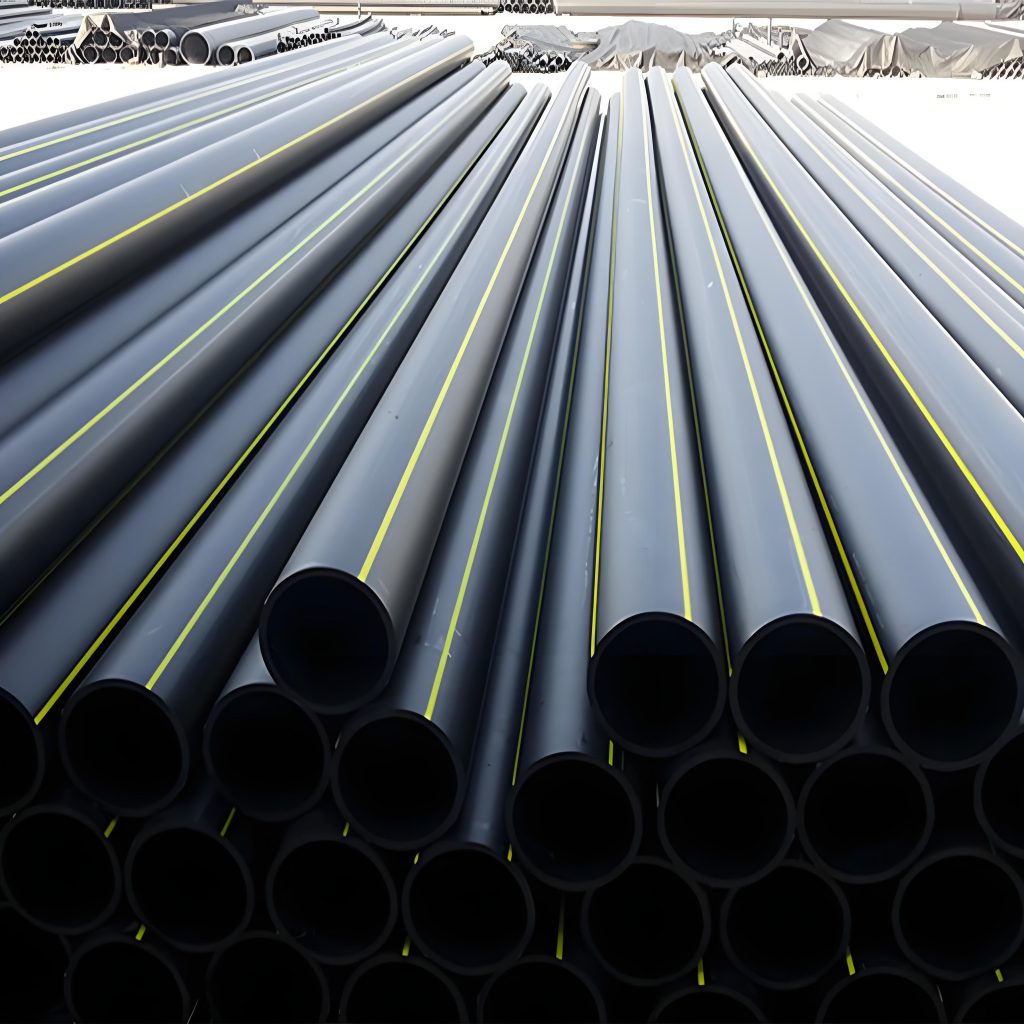

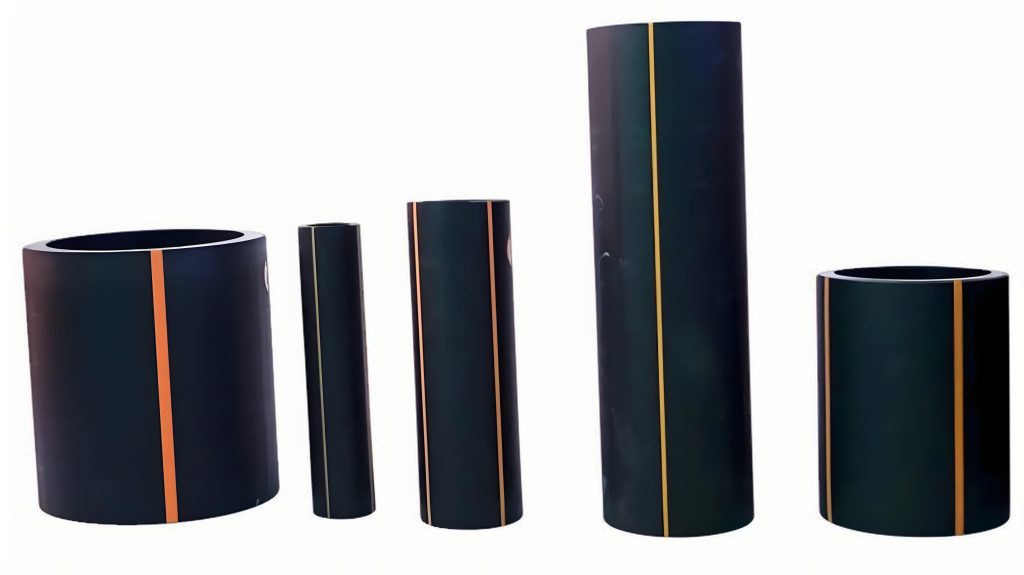

PE Water Pipe and Connection Technology

With the acceleration of urbanization and the enhancement of environmental protection awareness, PE (polyethylene) water pipes have gradually replaced traditional metal and PVC pipes as the preferred material for water supply, gas, agricultural irrigation and other fields due to their lightweight, corrosion-resistant and environmentally friendly characteristics. However, PE pipe performance advantages can be fully realized, the key lies in the correct connection technology.

1, PE water pipe: material properties and core advantages

1.1 What is PE water pipe?

PE (Polyethylene) is a thermoplastic resin, according to the density is divided into HDPE (high-density polyethylene) and LDPE (low-density polyethylene). HDPE is widely used in pressure piping because of its high strength, low temperature resistance (-60 ° C to 60 ° C) characteristics; LDPE for low-pressure scenarios, such as drip irrigation systems.

1.2 Five advantages of PE water pipe

Strong corrosion resistance: completely eliminates the rust and corrosion problems of metal pipes, with a service life of up to 50 years.

Flexible and impact-resistant: can be bent and laid to adapt to complex terrain, excellent seismic performance.

Health and environmental protection: non-toxic, odorless, in line with drinking water standards, low-carbon production process.

Lightweight and easy to install: the weight is only 1/8 of steel pipe, transportation and construction efficiency is greatly improved.

Low flow resistance and energy saving: smooth inner wall, not easy to scale for long-term use, reduce pumping energy consumption.

2, PE pipe connection technology: 3 mainstream methods

2.1 Hot melt connection method (most commonly used)

Principle: by heating the PE pipe end face melting, pressurized fusion into one, forming a permanent seal.

Applicable scene: diameter ≥ 63mm pipe, especially suitable for underground direct burial project.

Operation steps:

1. Cutting alignment: use special pipe cutter to make sure the cross-section is flat and burr-free.

2. heating plate preheating: set the temperature to 210 ± 10 ℃, the heating time is adjusted according to the diameter of the pipe (such as DN110 pipe takes about 45 seconds).

3. fusion pressurization: quickly remove the heating plate, apply 0.15MPa pressure to make the two ends of the molten layer combined.

4. Cooling and shaping: keep pressure and cool down to below 40℃ to avoid deformation of the interface.

Caution:

Extend the heating time when the ambient temperature is lower than 5℃.

Prohibit water or wet cloth to accelerate cooling to prevent brittle cracks.

2.2 Electrofusion connection method (precise and efficient)

Principle: Use the pipe fittings with built-in resistance wire to generate heat, melt the PE pipe and the inner wall of the pipe fittings to realize seamless connection.

Applicable scenes: narrow space operation or repair, suitable for DN20-DN315 pipe diameter.

Operation process:

1. surface treatment: scrape off the oxidized layer at the end of the pipe and mark the insertion depth.

2. Assembly of pipe fittings: Insert the pipe into the electrofusion sleeve to the marking line. 3.

3. Energized fusion: set the voltage and time according to the code of the pipe fittings (usually 220V, 3-30 minutes).

4. Natural cooling: Do not move the pipe during the cooling period.

Advantage:

High degree of automation, reduce human error.

Especially suitable for transition connection of pipes of different materials.

2.3 Mechanical connection method (flexible and fast)

Principle: Physical sealing is realized through flanges, clamps and other metal parts without heating.

Applicable scenarios: temporary works, non-pressure pipelines or frequently dismantled parts.

Common types:

Flange connection: PE flange head and steel flange bolted, need to add sealing gasket.

Clamp connection: Stainless steel clamp locking fittings with barbs, suitable for small diameter pipes.

Advantages and disadvantages:

Advantages: construction speed, can be disassembled and reused.

Disadvantages: long-term pressure may leak, need regular maintenance.

3, the key to connection quality

3.1 Interface leakage

Reason: insufficient heating time or uneven pressure.

Countermeasure: Use infrared thermometer to monitor the fusion temperature and ensure constant pressure.

3.2 Pipe Eccentricity

Cause: Pipe cutting is not perpendicular or fixture is not aligned.

Prevention: Use double-sided milling machine to deal with the end face, and use laser positioner to calibrate during installation.

3.3 False welding phenomenon

Manifestation: Bubbles or traces of non-fusion in the fusion area.

Treatment: Cut off and re-solder immediately, check the cleanliness and temperature stability of the heating plate.

3.4 Winter Construction Challenges

Challenge: Low temperature leads to prolonged melting time and too fast cooling.

Solution: Build a heat preservation shed, preheat the pipe to above 10℃ and use low temperature type electrofusion fittings.

4. How to select PE pipe and connection method?

4.1 Pipe selection guide

Pressure level: SDR11 (1.6MPa) is suitable for municipal water supply, SDR17 (0.6MPa) is used for drip irrigation.

Certification standards: recognize GB/T 13663 national standard or ISO 4427 international certification.

Color distinction: black (UV resistant, outdoor use), blue (drinking water), yellow (gas).

4.2 Decision tree of connection methods

Long-term buried works → hot melt connection

Space constraints or emergency repairs → electrofusion connection

Temporary/demountable demand → mechanical connection

5. Maintenance: the secret to extend the life of PE pipes

1. Regular inspection: check the UV aging of the exposed parts and wrap the protective layer if necessary.

2. Cleaning tips: use 0.3MPa low-pressure water flushing to avoid high-pressure water gun damage to the inner wall.

3. Frost crack prevention: add tracer tape in cold areas, or use deep burial (30cm below the permafrost layer).

PE water pipe and scientific connection technology, marking the pipeline engineering into a new era of high efficiency and environmental protection. Whether it is a family water supply renovation, or large municipal projects, mastering the correct selection and construction methods will maximize the advantages of PE materials. With the popularization of intelligent temperature control equipment and automated welding robots, PE pipe connection is developing in the direction of greater precision and reliability. Try PE pipe in your next project and experience the perfect combination of efficient construction and long-lasting benefits!

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a professional manufacturer and supplier of pipes and fittings. We offer PPR pipes, PVC pipes, PE pipes, and floor heating pipes and fittings for all types of pipes, with high quality and competitive prices. If you have any inquiries about pipes and fittings, please do not hesitate to contact us. You can click on the product to get in touch with us.