LUOYANG DATANG ENERGY TECH CO.,LTD

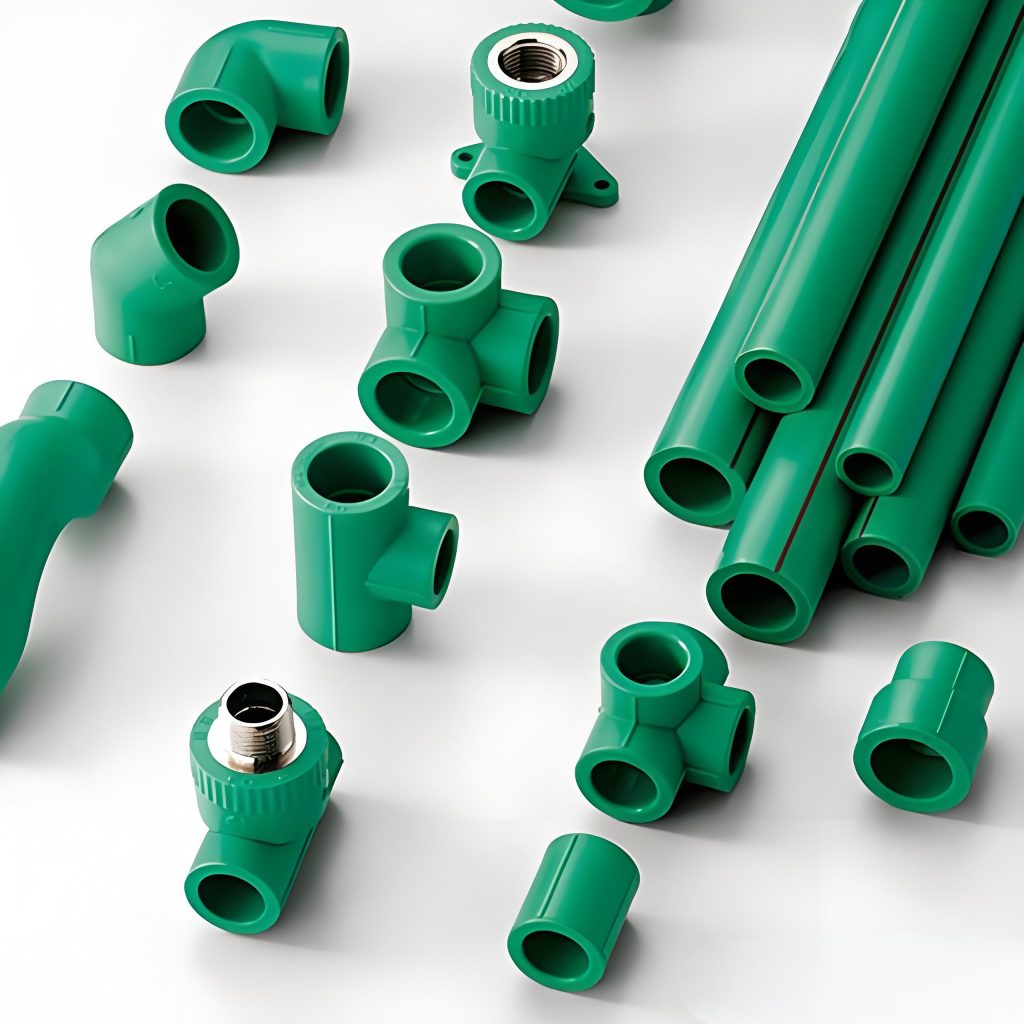

Exploring PPR Pipes: Key Properties, Applications, and Advantages

PPR pipes have broad applications in everyday life and industry.

What is a PPR pipe?

Polypropylene Random Copolymer (PPR) is a new type of plastic pipe material. Because of its excellent physical properties and chemical stability, it has been widely used in building water supply and drainage systems. Its remarkable structure gives it many unique properties.

The main characteristics of PPR pipe:

1. Heat resistance: PPR pipe can be used at higher temperatures, usually a working temperature of up to 95 ℃; a short period can even withstand high temperatures of up to 120 ℃.

2. Compressive strength: Compared with other plastic pipes, PPR pipes are more pressure-resistant, can withstand greater internal pressure, and are not easily ruptured.

3. Corrosion resistance: PPR material on most acids, alkalis, salt solutions, and grease substances is resistant to erosion, thus extending the service life.

4. Health and environmental protection: Per drinking water safety standards, PPR pipes do not contain harmful heavy metal components and will not release toxic substances.

5. Easy to install: Hot-melt connection technology makes the connection between the PPR pipe more solid, easy, and convenient to operate, reducing the difficulty of construction.

Choosing high-quality PPR pipe is critical to ensuring the long-term, stable operation of your home’s plumbing system. Below are some key points and steps to help you choose the best quality PPR pipe for your needs among the many brands and products available.

1. Check for certifications and standards

National Standards

In China, qualified PPR pipes should comply with the standard GB/T 18742-2002 “Polypropylene Piping Systems for Hot and Cold Water.” The standard specifies the basic technical requirements of PPR pipes, test methods, inspection rules, and other content and is an essential basis for measuring product quality.

International Certification

In addition to national standards, some international certifications, such as NSF (National Sanitation Foundation), DVGW (German Association of the Gas and Water Industry), and so on, are also important references for measuring the quality of PPR pipes. Products that have passed these certifications usually meet high environmental protection, health, and safety standards.

2. Material quality

Selection of raw materials

Quality PPR pipes are made from pure random copolymers of polypropylene, not recycled or blended materials. Pure PPR material has better heat resistance, compressive strength, and corrosion resistance. You can check the product’s composition statement to know whether it uses quality raw materials.

Surface smoothness

The surface of a high-quality PPR pipe should be very smooth, with no visible imperfections or unevenness. A smooth surface is not only aesthetically pleasing but also indicates that the molds used in the production process are highly accurate, which helps to improve the pipe’s overall performance.

3. Level of artistry

Quality of heat fusion connection

PPR pipes are usually connected by heat fusion, so the connection quality directly affects the sealing and stability of the whole system. High-quality PPR pipes can form a solid and uniform joint after heat fusion to avoid the risk of water leakage.

Production process

Advanced production processes ensure the consistency and reliability of PPR pipes. For example, the extrusion molding process determines whether the wall thickness is uniform, essential for the pipe’s resistance to pressure and service life. You can ask the manufacturer about the production process or check the relevant product information when buying.

4. Brand Reputation

Market reputation

Choose a well-known brand of PPR pipe is often more secure. Well-known brands usually have a more stringent quality control system and have a good market reputation. You can learn about the performance of different brands through online evaluation and user feedback.

After-sales service

A good brand provides high-quality products and perfect after-sales service. This includes installation guidance, technical support, and product warranty. Choosing a brand with good after-sales service will help you get timely help and support when problems arise.

5. Actual test

Pressure resistance test

You can assess the pressure resistance of PPR pipes by checking the pressure resistance test data in the product manual. Generally speaking, domestic hot and cold water piping systems require PPR pipes to operate stably under a certain pressure for a long time.

Temperature resistance test

Similarly, temperature resistance is one of the most important indicators of the quality of PPR pipes. A good PPR pipe should be able to maintain good physical properties at higher temperatures without deformation or rupture.

6. Installation and Maintenance

Correct installation method

Even if you choose a high-quality PPR pipe, its performance will be affected if installed incorrectly. Therefore, the installation process should strictly follow the requirements of the product manual, especially the hot melt connection part, which must ensure sufficient heating and cooling time.

Regular inspection and maintenance

To prolong the service life of PPR piping, it is recommended that the piping system be inspected and maintained regularly. Observe for leakage or seepage and replace the aging or damaged parts in time.

Applications of PPR pipes

With their excellent physical and chemical properties, PPR pipes play an important role in many fields, such as domestic, industrial, and commercial buildings, and have become an indispensable part of modern construction projects. In many applications, their excellent performance allows them to satisfy diversified needs.

Domestic applications

In residential buildings, PPR pipes are commonly used in hot and cold water supply systems to provide safe and reliable water transfer and meet daily water needs.

Industrial applications

In industry, PPR pipe is used to transport a wide range of liquids and is favored for its corrosion resistance and good mechanical strength. It can cope with a wide range of chemicals and different working pressures, making it suitable for different types of industrial fluid transportation needs.

Heating, ventilation, and air conditioning (HVAC) systems

PPR pipes provide adequate heat transfer and support efficient system operation in HVAC systems. They are used for radiator connections, underfloor heating piping, and more to give the buildings a comfortable indoor environment.

Underfloor Heating Systems

As an ideal material for underfloor heating pipes, PPR pipes work stably in underground environments, have excellent thermal insulation properties, and have a long service life, making them one of the preferred materials in modern underfloor heating installation projects.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a professional manufacturer and supplier of pipes and fittings. We offer PPR pipes, PVC pipes, PE pipes, and floor heating pipes and fittings for all types of pipes, with high quality and competitive prices. If you have any inquiries about pipes and fittings, please do not hesitate to contact us. You can click on the product to get in touch with us.