LUOYANG DATANG ENERGY TECH CO.,LTD

PEX Floor Heating Pipe vs Copper /PE-RT Pipe

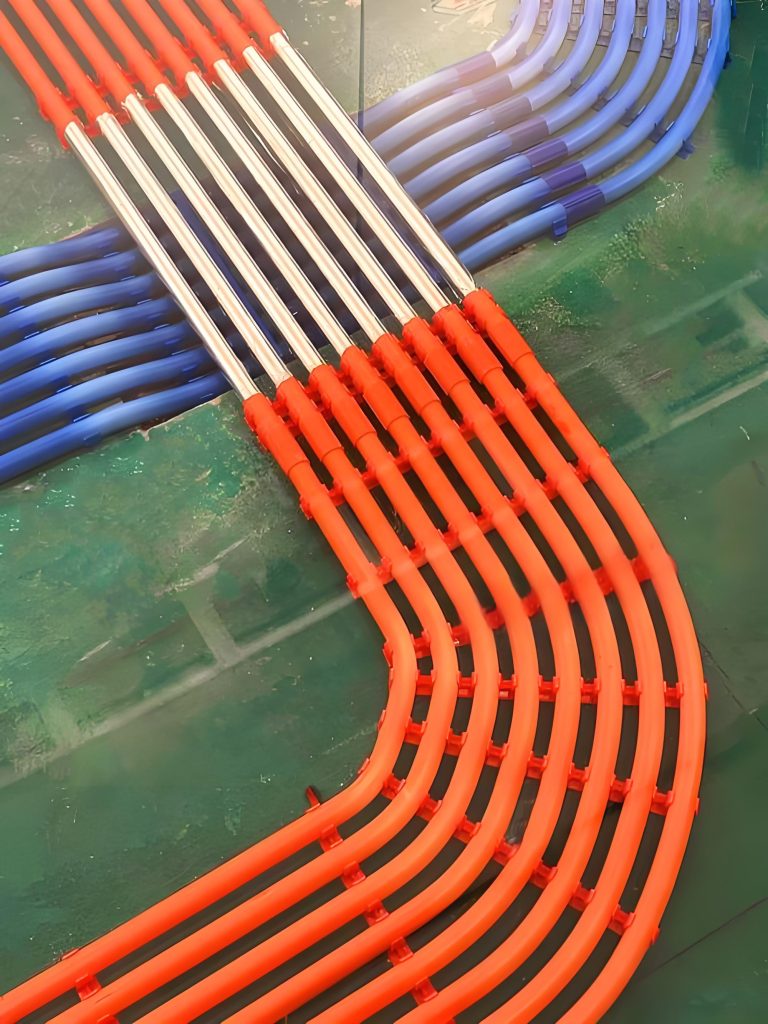

In a low-temperature radiant floor heating system, pipes are like the blood vessels of the human body, directly affecting heating efficiency, energy consumption and long-term use experience. With the advancement of material technology, PEX (crosslinked polyethylene) pipe, copper pipe and PE-RT (high temperature resistant polyethylene) pipe have become mainstream choices. In this article, we will compare the four dimensions of material characteristics, corrosion resistance, thermal conductivity efficiency and installation cost to help you make cost-effective decisions.

First, material comparison: flexibility, life and environmental protection

1.PEX floor heating pipe: balance of flexibility and durability

PEX pipes are crosslinked to form a three-dimensional mesh structure that combines the flexibility and strength of polyethylene. Its advantages include:

Deformation resistance: -70℃~110℃ tolerance range, can resist the floor heating cycle cold and hot shock.

Memory resilience: it can recover by itself after accidental flattening during construction to reduce the risk of leakage.

Environmental protection: no risk of heavy metal precipitation, in line with European Union RoHS standard.

2.Copper pipe: the limitations of traditional metal pipe

Copper pipe is known for its high thermal conductivity, but there are obvious shortcomings:

High hardness, difficult to bend: need a large number of joints, increase the potential leakage.

Oxidation and electrolytic corrosion: especially in alkaline or sulfur-containing water easy to produce patina.

Cost-sensitive: The price of raw materials is significantly affected by the fluctuations of international copper price.

3.PE-RT tube: the middle choice of cost-effective

PE-RT improves temperature resistance through molecular structure modification, but compared with PEX:

Weak pressure resistance: it is easy to creep under long-term high temperature, and its service life is about 20-30 years (PEX can reach more than 50 years).

Limited application scenario: more suitable for low temperature heating system below 60℃.

Conclusion: PEX wins in life and adaptability, especially suitable for complex pipe distribution.

Corrosion resistance: the ultimate test of water quality and environment

PEX tube: the king of chemical inertia

No reaction to acid, alkali and salt solution (pH 2-12), chloride ions, no need to clean regularly.

Case: 90% of the floor heating in Northern Europe uses PEX pipes to deal with high mineral groundwater without pressure.

Copper pipe: potential minefield of corrosion risk

Electrochemical corrosion: it is easy to form local battery effect in water with high oxygen content.

Sulfide corrosion: the water in some areas of China is high in sulfur, which is easy to form black copper sulfide scale.

Maintenance cost: need to add corrosion inhibitor regularly, annual maintenance cost of about 300-500 /100㎡.

PE-RT tube: stability is inferior to PEX

After long-term use, it may cause embrittlement due to oxidation, and the joint is easy to crack.

Conclusion: PEX is almost maintenance-free, especially suitable for complex water quality environment in China.

Thermal conductivity Efficiency: The misunderstood “metal advantage”

1.Data comparison

| MATERIALS | Thermal conductivity (W/m·K) | Measured heat dissipation efficiency(W/ m ²) |

| Copper pipe | 380 | 85-90 |

| PEX tube | 0.41 | 75-80 |

| PE-RT tube | 0.38 | 70-75 |

2.Metal thermal conductivity ≠ actual advantage

Thermal inertia: copper pipe has strong heat storage, leading to slow temperature rise/cooling, which is not conducive to accurate temperature control.

Offset by heat loss: the copper tube requires additional insulation (20% more cost), and PEX has low thermal conductivity.

Uniformity: PEX tubes can be densely-coiled to compensate for thermal conductivity differences and achieve more balanced heat dissipation.

Conclusion: The actual heating effect of PEX is close to that of copper tube, and the energy saving is improved by 10%-15%.

Installation cost: a money-saving code for hidden projects

Comprehensive cost comparison (taking 100㎡ house as an example)

| Project | PEX tube | Copper tube | PE-RT tube |

| Cost of materials | $4000 | $12,000 | $3,500 |

| Labor | $2,500 | $6000 | $3,000 |

| Maintenance fee (10 years) | $200 | $3000 | $800 |

| Total cost | $6,700 | $21000 | $7300 |

PEX construction advantages

Single pipe continuous laying: no joint design to reduce 90% leakage points.

Tool simplification: special clamping tool instead of copper pipe welding, shorten the construction period by 40%.

High fault tolerance: support non-professional DIY repair (such as the use of hot melt sleeve).

Conclusion: The comprehensive cost of PEX is only 1/3 of that of copper pipe, and the later maintenance is almost zero investment.

Final Choice: Why is PEX the future Trend?

1.Trends from industry data

PEX will account for 68% of the global floor heating pipe market in 2025 (data source: GIA report).

The adoption rate of PEX in newly installed residential floor heating systems in China jumped from 32% in 2015 to 79% in 2025.

2.Scenario-based recommended

Preferred PEX: suitable for 90% of families, especially the transformation of old houses and complex units.

Carefully select copper pipe: It is only recommended for commercial places (such as gyms) with UHF start and stop, and soft water system is required.

PE-RT alternative: southern areas with extremely limited budgets and short heating seasons.

The iterative nature of underfloor heating pipe is an upgrade in user value — PEX achieves higher reliability at lower cost, which is the perfect combination of materials science and engineering wisdom.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a professional manufacturer and supplier of pipes and fittings. We offer PPR pipes, PVC pipes, PE pipes, and floor heating pipes and fittings for all types of pipes, with high quality and competitive prices. If you have any inquiries about pipes and fittings, please do not hesitate to contact us. You can click on the product to get in touch with us.