LUOYANG DATANG ENERGY TECH CO.,LTD

PE, PVC and PPR Pipes in Drainage and Sewage Systems (DWV)

In the plumbing system of modern buildings, the Drain, Waste, Vent system (DWV) is the core link to ensure the functionality and hygiene safety of the building. As experts in pipe production, we know that the performance differences of pipes made of different materials directly affect the lifespan and maintenance costs of the project. This article will provide an in-depth analysis of the unique advantages and applicable scenarios of PE pipes (polyethylene), PVC pipes (polyvinyl chloride), and PPR pipes (random copolymer polypropylene) in DWV systems to help you precisely match project requirements.

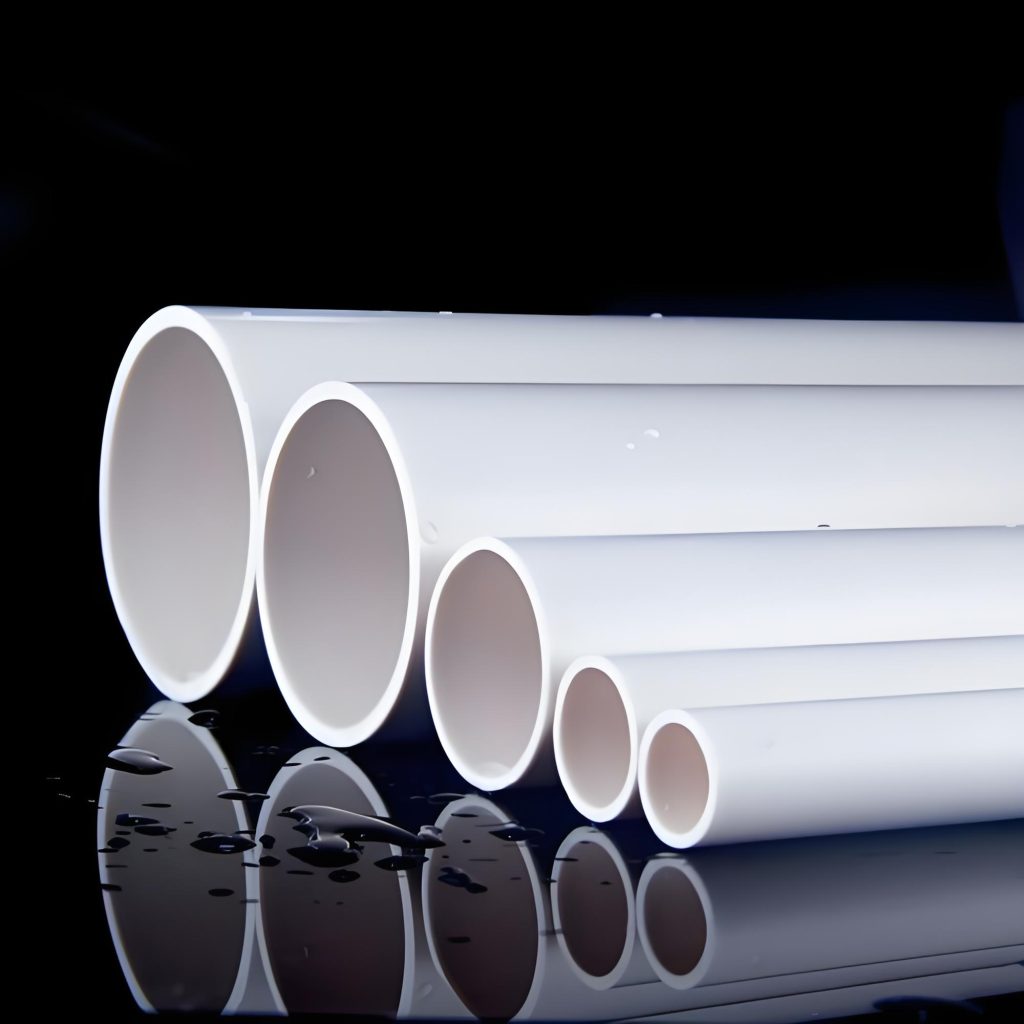

PVC pipes: The first choice for lightweight and high cost performance

PVC pipes have long dominated the DWV system market due to their lightweight, low cost, and chemical resistance. Its rigid structure effectively resists soil pressure and is suitable for underground drainage pipe installation.

Core advantages:

1. Excellent acid and alkali resistance: Can withstand corrosive substances such as grease and cleaning agents in domestic sewage for a long time.

2. Easy to install: The glue bonding process is used, the connection is fast and the labor cost is low.

3. Low flow resistance: The inner wall is smooth, reducing the risk of dirt deposition and the probability of clogging.

Applications:

– Vertical drainage main pipes in residential buildings

– Underground sewage pipe network for commercial buildings

– Branch exhaust lines of the ventilation duct system

Construction tips: Avoid exposure to ultraviolet environments (buried or protected), and the working temperature is recommended to be controlled between -5 ° C and 60 ° C.

PE pipes: A flexible and impact-resistant buried solution

High-density polyethylene (HDPE) pipes are known for their exceptional flexibility, freeze crack resistance, and wear resistance, making them particularly suitable for DWV projects in complex terrain and cold regions.

Core advantages:

1. Excellent impact resistance: It can withstand ground settlement and vehicle pressure, reducing the risk of pipeline rupture.

2. Zero leakage in hot-melt connection: Seamless connection is achieved through an electric fusion welding machine, eliminating leakage at the interface.

3. Long life design: up to 50 years or more in the absence of direct ultraviolet radiation.

Application scenarios:

– Underground main sewage network in industrial parks

– Connecting pipes for septic tanks in cold regions

– Flexible drainage systems for buildings in seismic zones

Construction tips: Special hot-melt equipment is required, and the construction team must hold PE pipe welding certification.

PPR pipes: Green materials that can withstand high temperatures

While PPR pipes are more often used in water supply systems, their heat-resistant, non-toxic and environmentally friendly properties make them stand out in special DWV scenarios.

Core advantages:

1. High temperature stability: Can withstand 95 ° C high temperature wastewater (such as laboratory and kitchen drainage) for a long time.

2. Ecological safety: Compliant with food-grade standards, suitable for sensitive places such as hospitals and food factories.

3. Low coefficient of thermal expansion: reduces pipe deformation caused by temperature differences.

Application scenarios:

– Hospital high-temperature disinfection wastewater discharge system

Oily wastewater pipelines in food processing plants

– Condensate drainage pipes for solar water heaters

Construction tips: Use hot-melt socket connection and precisely control the heating time to avoid tube wall deformation.

The performance comparison table of the three major pipes

| Indicators | PVC pipes | PE pipe | PPR pipe |

| Temperature range | – 5 ℃ ~ 60 ℃ | – 30 ℃ ~ 60 ℃ | – 20 ℃ ~ 95 ℃ |

| Connection method | Adhesive connection | Hot melt welding | Hot-melt socket |

| Impact resistance | Medium | Extremely High | Medium |

| Typical cost (yuan/m) | 15-30 | 25-50 | 20-40 |

| Best applicable scenarios | Regular drainage | Buried/High cold areas | High-temperature wastewater discharge |

Selection Decision Guide

1. Budget priority items: Choose PVC pipes to reduce initial investment.

2. Geological complex areas: The flexibility of PE pipes can withstand foundation deformation.

3. High-temperature discharge requirements: PPR pipes are essential for the medical/food industry.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PVC Pipe & PE Pipe in DWV system, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net