LUOYANG DATANG ENERGY TECH CO.,LTD

HDPE Pipe and Fittings:An Innovative Solution for Drainage & Sewage System

With the acceleration of urbanization, the reliability and efficiency of drainage systems have become core requirements for municipal engineering, industrial facilities and construction projects. Among many pipe materials, HDPE pipes (high-density polyethylene pipes) are gradually becoming the preferred choice for stormwater drainage, sewage transportation and combined drainage due to their excellent physical properties, corrosion resistance and long service life. This article delves into the advantages of HDPE pipes in drainage and sewage systems, and explains how they meet the demands of complex scenarios through their properties such as pressure resistance, clogging resistance, and corrosion resistance.

Advantages of HDPE pipes and fittings in drainage & sewage system

1. Excellent pressure resistance

HDPE pipes are made of high-density polyethylene material, whose unique molecular structure gives the pipes extremely high ring stiffness and impact resistance. In stormwater drainage systems in heavy-duty areas such as roads and squares, HDPE pipes can withstand the pressure of vehicles and soil, avoiding cracking or leakage caused by external force deformation. In addition, the flexibility of HDPE enables it to adapt to foundation settlement, reducing the risk of system failure caused by ground displacement.

2. Efficient anti-clogging design

Conventional metal or concrete pipes are prone to shrinking inner diameters due to rust, scaling or debris accumulation, while HDPE pipes have a smooth inner wall with an extremely low coefficient of friction (only 0.009), which significantly reduces the adhesion of solid particles in sewage. In scenarios where domestic sewage and industrial wastewater are transported, this feature not only reduces the probability of clogging, but also reduces maintenance frequency and operating costs.

3. Corrosion resistance and long service life

HDPE is much more resistant to acids, alkalis, salts and chemicals than metal pipes, and is particularly suitable for the discharge of industrial wastewater containing corrosive components, such as electroplating wastewater and chemical wastewater. It has a design life of more than 50 years, significantly reducing the cost of secondary investment due to pipe replacement.

4. Lightweight and quick installation

HDPE pipes weigh only 1/8 the weight of steel pipes and support hot-melt connection technology, eliminating the need for complex welding or flange butt joints, which can shorten the construction period by more than 30%, especially suitable for municipal projects with tight schedules.

Application of HDPE pipe and fittings in drainage and sewage systems

1. Rainwater drainage: roads, squares and urban flood control

In stormwater drainage systems for roads and squares, HDPE pipes withstand vehicle loads and soil pressure through high ring stiffness designs (e.g. SN8 or above) to ensure long-term stable operation. Its flexibility can also adapt to surface deformation in extreme weather, reducing the risk of pipe breakage caused by heavy rain.

Case application: A city’s main road used HDPE double-wall corrugated pipes to build a rainwater network, successfully coping with continuous heavy rainfall without water accumulation or pipe damage.

2. Sewage discharge: domestic sewage and industrial wastewater

HDPE pipes, with their corrosion resistance and smooth inner walls, have become ideal carriers for transporting domestic sewage (containing grease and organic matter) and industrial wastewater (containing acids, alkalis and heavy metals). The joint seal can prevent sewage from seeping and polluting groundwater, in line with environmental protection regulations.

Technical highlights: For the highly oily wastewater from food processing plants, HDPE pipes with dedicated anti-clogging fittings (such as large curvature elbows) can reduce clogging problems caused by grease accumulation.

3. Efficient integration of combined sewer and drainage systems

In combined drainage scenarios, HDPE pipes can handle the mixed transportation requirements of rainwater and sewage simultaneously. By customizing the design (such as increasing the pipe diameter or pressure rating), it can adapt to complex conditions with large flow fluctuations, avoiding overflow and system overload.

Why Choose our HDPE pipes and Fittings?

1. Full range of product certification and quality assurance

Our HDPE pipes and fittings are certified by ISO 9001 quality management system and comply with international standards such as GB/T 19472.1-2004 and ASTM F714, ensuring full traceability from raw materials to finished products.

2. Customized solutions

For different scenarios, we offer:

Reinforced pressure-resistant pipes: suitable for deep burial or heavy load areas;

High-temperature resistant fittings: Suitable for high-temperature discharge of industrial wastewater (up to 60 ° C);

Modular design: Supports quick assembly to reduce construction difficulty.

3. Environmental protection and sustainability

HDPE material is 100% recyclable, and its production process consumes 40% less energy than traditional materials, helping customers achieve green building and low-carbon goals.

How to optimize the design of HDPE pipes in drainage and sewage systems?

1. Precise selection: Select the ring stiffness grade (e.g. SN4, SN8, SN16) based on flow rate, pressure and soil conditions;

2. Scientific layout: Utilize computer simulation technology to optimize the pipeline network direction and reduce the number of elbows to lower resistance.

3. Regular maintenance: Use CCTV pipeline inspection robots to identify potential blockages and extend the system’s lifespan.

Supplier

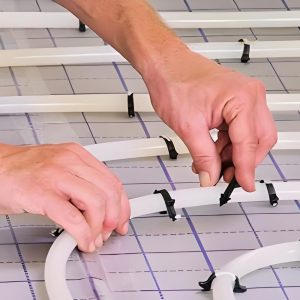

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PVC Pipe & PE Pipe in Agricultural Irrigation, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net