LUOYANG DATANG ENERGY TECH CO.,LTD

Brass Plumbing Manifolds:The Durable Core of Modern Piping Systems

In modern buildings and industrial facilities, the stability and reliability of plumbing systems are of Paramount importance. As the core component of pipe distribution, Brass Plumbing Manifolds (brass diverters) have become the preferred accessory for HVAC, water supply systems and industrial equipment worldwide due to their outstanding performance.

1. What is Brass Plumbing Manifolds?

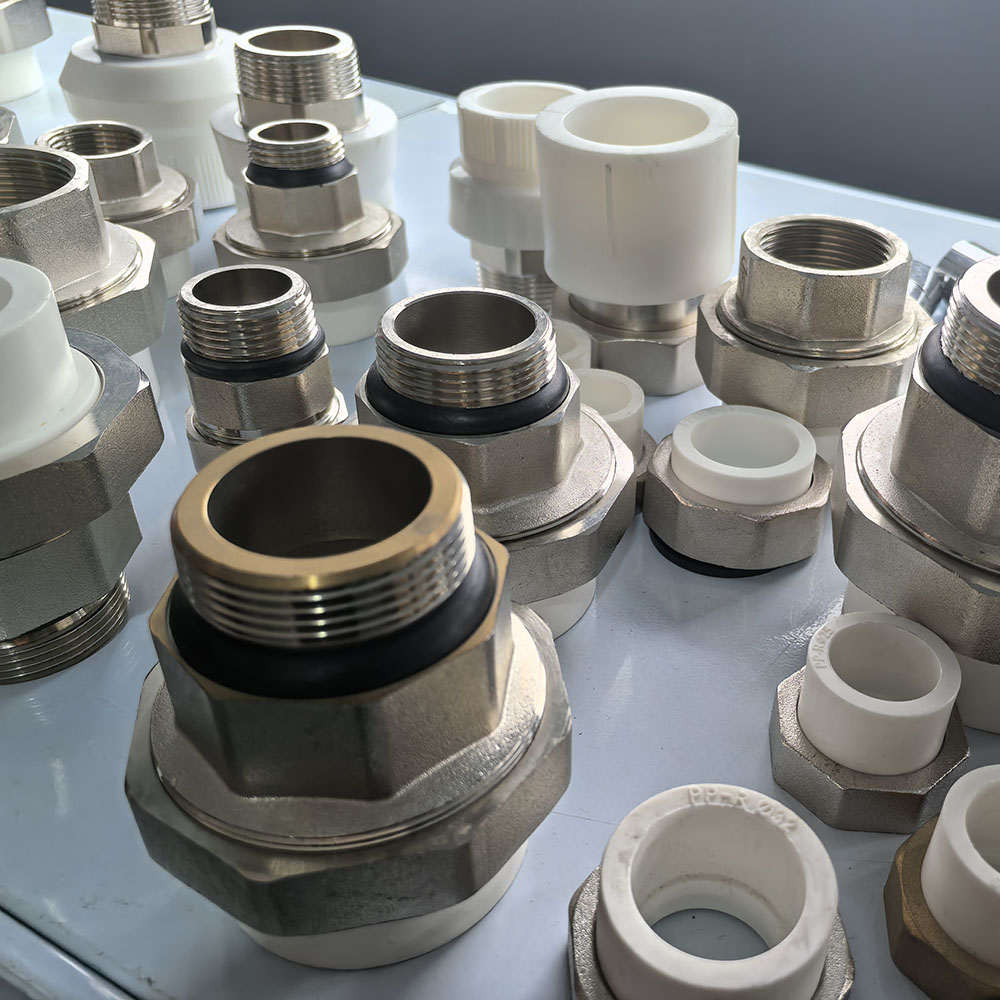

Brass Plumbing Manifolds (brass shunt) is a pipe connection device used for centralized distribution or control of fluids (such as water, gas), usually cast from high purity brass materials. Its core function is to divide a single input source into multiple output ports through a multi-channel design, or reverse integrate multiple input sources to achieve precise control of the fluid.

Unique advantages of brass material:

1. Strong corrosion resistance: brass copper zinc alloy, natural resistance to scale, chloride ions and chemical erosion, life can reach more than 20 years

2. High temperature and high pressure resistance: working temperature range -50°C to 200°C, bearing capacity of more than 50Bar

3. Bacteriostatic environmental protection: Copper ion can inhibit microbial growth, in line with drinking water sanitation standards (such as NSF/ANSI 61 certification)

4. Excellent sealing performance: precision machined thread interface to ensure zero leakage

Modern high-end brass shunt adopts CNC machine tool precision processing, with the surface nickel/chromium plating process, to further strengthen the anti-oxidation ability, adapt to the needs of complex working conditions.

2, The six core applications of Brass Plumbing Manifolds

1. Residential and commercial building water supply system

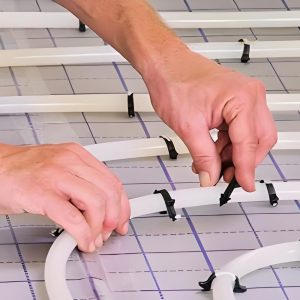

Floor heating water distributor: evenly distribute hot water to each room line

Central water purification system: flow control hub between multistage filtration equipment

Bathroom branch pipe distribution: realize the independent pressure control of the washbasin, shower, toilet and other terminals

2. Industrial equipment cooling cycle

Injection molding machine, laser cutting machine cooling pipe distribution

Distribution and recovery of media in chemical production

3. Agricultural irrigation systems

The flow of greenhouse drip irrigation network is evenly distributed

Regional control nodes of large sprinkler irrigation systems

4. Ships and offshore facilities

The multistage treatment pipeline of the desalination unit is connected

Ship’s ballast water management system

5. Fire sprinkler system

Flow control of fire protection pipe network in high-rise buildings

6. New energy field

Solar water heater heat collection – water storage cycle control

Coolant distribution for hydrogen energy batteries

3. Made in China: The benchmark of cost performance of global brass shunt

As the world’s largest producer of brass products, China accounts for more than 65% of the global brass fittings market share (source: International Copper Association). Relying on a complete industrial chain and mature process system, Chinese producers are redefining the value standard of high-end industrial accessories.

Four major competitiveness of Chinese Brass Plumbing Manifolds:

1. Cost advantage

Local copper and zinc resources are rich, raw material procurement cost is 30% lower than Europe and the United States

Large-scale production reduces marginal costs and supports flexible delivery of customized orders

2. Technological innovation

Using German DMG five-axis machining center, tolerance accuracy up to ±0.01mm

Self-developed low pressure casting process, porosity is less than 0.2%

3. Quality certification

Mainstream manufacturers through ISO 9001, CE, RoHS, WRAS and other international certification

Third-party laboratories provide testing reports such as salt spray testing (500 hours without rust) and bursting pressure testing

4 Upgrade the service

Support 3D drawing customization, the fastest 7 days proofing

Provide OEM/ODM foundry, meet the thread standards of different countries (such as NPT, BSPP, BSPT)

4. How to choose quality Chinese suppliers?

In the face of hundreds of suppliers in the market claiming “quality and low price”, buyers need to focus on the following dimensions:

1. Material traceability capability

Required to provide material proof of copper (such as C37700, CZ121, etc.)

Refuse to recycle copper remelting cast products (easy to lead to zinc loss and strength loss)

2. Process control system

Check the X-ray inspection report of the production site

Confirm seal test with helium mass spectrometer leak detector (accuracy up to 1×10⁻⁹ mbar·L/s)

3. Case verification

Ask for past projects exported to the EU and North American markets

Preference is given to factories that work with international brands such as Grundfos and Johnson Controls

4 Do comprehensive cost accounting

Compare the balance of FOB price with MOQ (minimum order quantity)

5. Evaluate suppliers’ VMI (Vendor Managed Inventory) capabilities to reduce warehouse stress

Future trend: Intelligent integration and green manufacturing

1. Intelligent upgrade

Integrated pressure/temperature sensor, support IoT remote monitoring

Electronically controlled proportional valve linkage, to achieve automatic flow regulation

2. Sustainable development

Bio-based cutting fluid is used to reduce pollution

Develop lead-free Brass (such as Eco Brass®) to meet the RoHS 3 directive

As a leading Brass Plumbing Manifolds manufacturer in China, we always adhere to strict quality inspection to ensure that every product delivered meets ASME B16.24 standard. Whether it is a small retail order or a large engineering project, we provide one-stop services from selection consultation, rapid proofing to logistics customs clearance.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding PVC Pipe,PPR Pipe & HDPE Pipe , please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net