LUOYANG DATANG ENERGY TECH CO.,LTD

Eco-Friendly PPR Pipes: Expert Guide to Avoid Cheap Materials & Failures

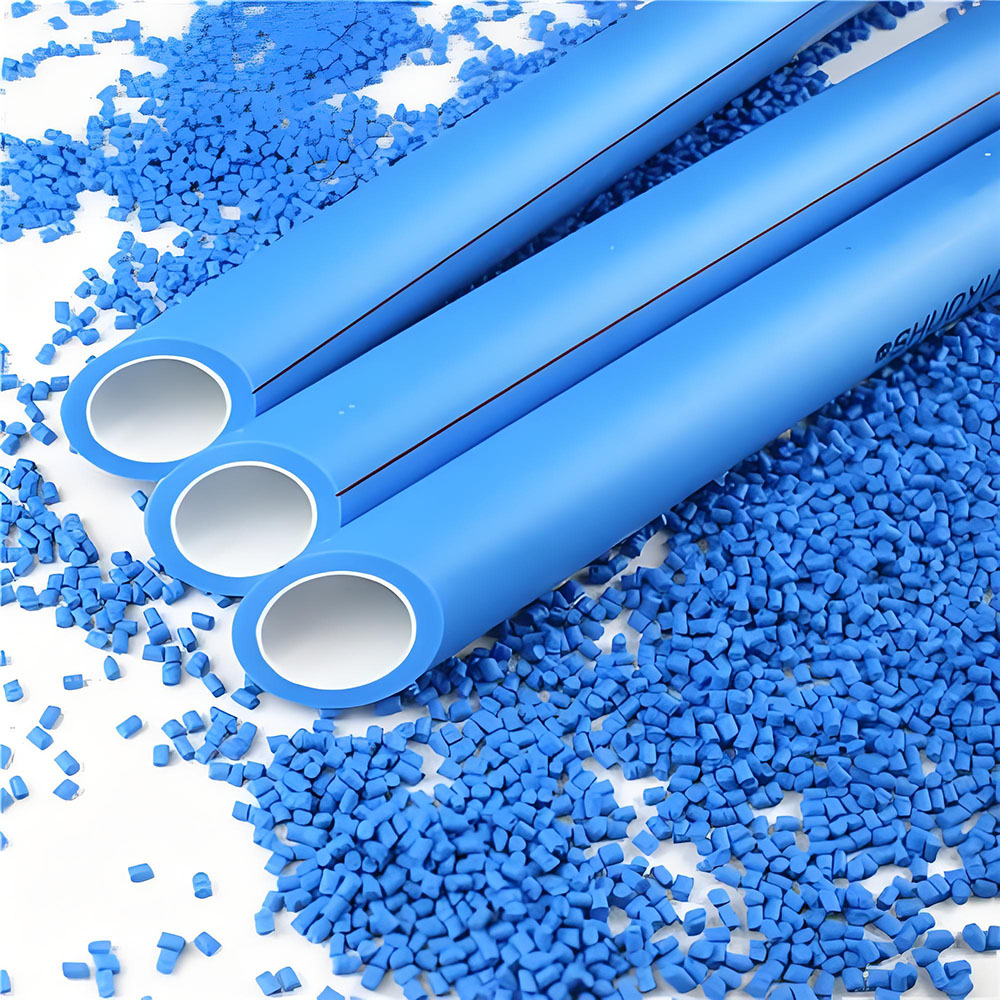

The selection and installation of PPR (Polypropylene Random Copolymer) pipes and fittings is directly related to the safety and convenience of family water system.PPR water pipe has corrosion resistance, high temperature resistance, easy to install and other characteristics, has become the preferred material for modern home plumbing system.

First, What is the material composition of PPR water pipe?

1.1 PPR water pipe characteristics

Strong corrosion resistance: PPR material can resist a variety of chemical substances erosion, not easy to rust or scale, to ensure clean water.

High temperature resistance: Suitable for high temperature hot water system, can withstand high temperature changes within a certain range, not easy to deformation or aging.

Easy installation: Hot melt connection method, without complicated joint treatment, fast installation speed, good sealing performance.

ECO-friendly: Non-toxic and harmless, in line with drinking water safety standards, to ensure the health of the family.

1.2 Specifications and selection

PPR water pipes are divided into different diameters and pressure levels according to use scenarios and needs. Common diameters are 20mm, 25mm, etc., and pressure levels range from PN1.0 to PN2.5. When choosing, it is necessary to consider comprehensively according to the household water consumption, equipment layout and water heater type to ensure that the water pipe can meet the flow demand and withstand the system pressure.

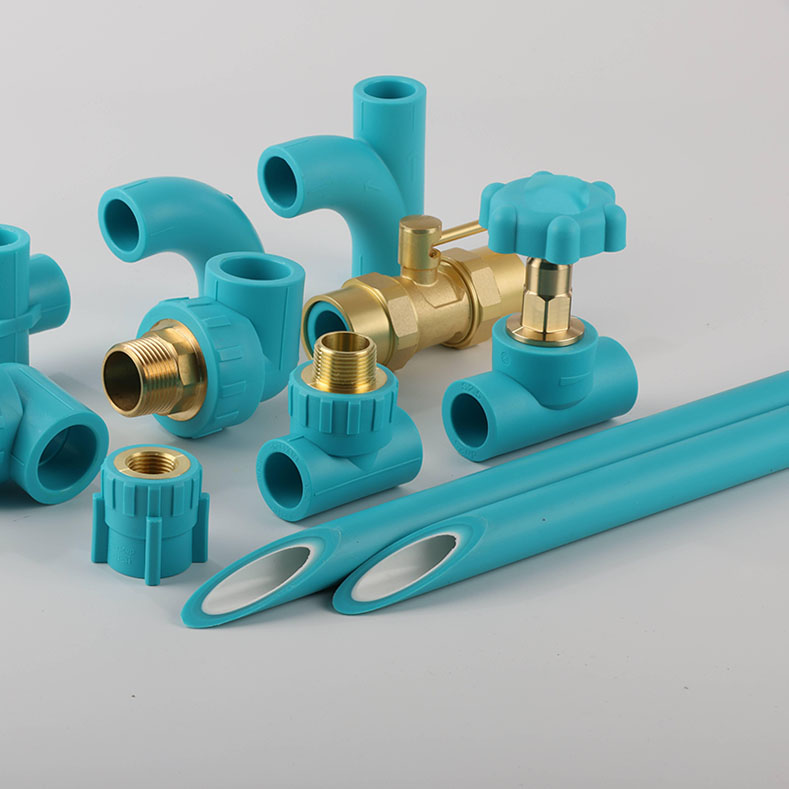

Second, PPR Pipe Fittings Series & Purchase Guide

When you read a PPR water pipe and fitting demand list, understanding the common PPR pipe fittings name and function is the first step in accurate procurement.

2.1 MALE TEE & FEMALE TEE

MALE TEE: The thread is located outside the pipe fittings, usually used to connect the faucet, valve and other equipment, easy to tighten and fix.

FEMALE TEE: The thread is located inside the pipe fitting, used to connect another section of water pipe or accessories with external thread to achieve seamless connection.

2.2 COUPLING,ELBOW,TEE & CROSS

COUPLING: Used to connect two water pipes in a straight line to keep the water flow direction unchanged.

ELBOW: To change the water flow direction, the common Angle is 45°, 90°, selected according to the layout requirements.

TEE: Connects three PPR water pipes to realize branch water supply. It is often used in the layout of multiple water points such as kitchen and bathroom.

CROSS: Connects four PPR water pipes, suitable for more complex waterway design, such as centralized water supply system.

2.3 VALVE & WATER TAP

VALVE: Water flow control switch, divided into globe valve, ball valve, etc., used for emergency closure of water or water regulation.

WATER TAP: Household water terminal, according to the use of places are divided into kitchen faucet, bathroom faucet, etc., pay attention to the selection of material, outlet mode and water-saving performance.

2.4 Other Auxiliary Accessories

Hot Melt Machine: A must-have installation tool, used to heat PPR water pipes and fittings for seamless welding.

Pipe Card: Fix the water pipe to prevent vibration or displacement and ensure the stability of the waterway system.

Thermal Insulation Material: Thermal insulation of water PPR pipes should be considered in cold areas to reduce heat loss and prevent water pipes from freezing.

Three, Preparation Before PPR Pipe Installation

3.1 Waterway design drawing

Draw detailed water layout drawings based on the home layout and water needs. Mark the direction of the water pipe, the location of the pipe fittings, the distribution of valves, etc., to ensure that there is evidence to follow during the installation process.

3.2 Site measurement and material procurement

Carry out on-site measurement according to the design drawing, and accurately calculate the required pipe length, pipe fitting quantity and specifications. When purchasing, consider a certain margin for emergency needs, while ensuring that all materials are in line with national standards, reliable quality.

3.3 Check before PPR water pipe installation

Appearance inspection: Ensure that the surface of the water pipe and pipe fittings is smooth and non-destructive, without cracks, dents and other defects.

Inner wall inspection: Use a flashlight or other tools to check whether the inner wall is smooth and unobvious, without impurities blocked.

PPR pipe fittings: Make sure that all pipe fittings match the specifications of the water pipe, the thread is clear, and it is easy to connect.

Four,Steps of PPR Pipe Installation

4.1 Hot Melt Machine

Preheat the hot melt: Adjust the temperature of the hot melt according to the water pipe specifications, and preheat the hot melt to the appropriate range.

Cutting PPR water pipe: Use special scissors or a pipe cutter to make sure that the incision is smooth and without burrs.

Welding connector: Insert the water pipe and pipe fitting into the hot melt head, heat to the specified time, and then docking quickly, keep certain pressure until cooling and curing.

4.2 Layout And Fixing

Follow the design drawing: Layout the water pipes strictly according to the design drawing to avoid improper flow or safety risks caused by random modification.

Reasonably fixing: Fix the water pipe to the wall or floor using pipe clips to keep the straight or curved parts stable.

Reserved space: Reserve sufficient operating space at the connection points of faucets, valves, etc., for future maintenance or replacement.

4.3 Inspection And Testing

Pressure test: After the installation is complete, perform a system pressure test to check all connection points for leakage.

Drainage test: Turn on all taps to check that the water flow is smooth and there is no abnormal noise or vibration.

Record information: Record the layout of the water pipe, the position of the valve and the precautions for use, so as to facilitate future maintenance and management.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding our Healthy PPR Pipes and Fittings, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net