LUOYANG DATANG ENERGY TECH CO.,LTD

Why HDPE pipes are the best choice?

In the choice of pipe materials, HDPE pipe (polyethylene pipe) with its excellent performance and cost effectiveness, gradually become the best choice for various pipe applications. From urban water supply, agricultural irrigation to industrial pipeline systems, HDPE pipes have gradually replaced traditional PVC pipes, steel pipes and cast iron pipes and become more competitive materials because of their durability, environmental protection and easy installation. HDPE (high density polyethylene) pipe has gradually become the darling of the market because of its excellent performance.

1. The basic characteristics of HDPE pipes

HDPE pipeline is a kind of pipeline made of high-density polyethylene plastic, which is widely used in many fields such as water supply, drainage, natural gas transmission, power communication and agricultural irrigation. HDPE pipe has become the ideal pipeline solution due to its high strength, corrosion resistance, low temperature resistance, easy installation and maintenance. It not only has outstanding performance in quality and performance, but also has incomparable advantages in environmental protection.

2. Comparison with PVC pipe: more durable

PVC (polyvinyl chloride) pipe is one of the most common materials in the pipeline industry, because of its low cost, good corrosion resistance and easy to manufacture characteristics, is widely used in water supply, drainage and other fields. However, when PVC pipes are compared with HDPE pipes, there are some shortcomings.

2.1 Impact resistance and aging resistance

PVC pipes are inferior to HDPE pipes in impact resistance and aging resistance. Although the service life of PVC pipes is longer in dry, normal temperature environment, the performance of PVC pipes is easy to decline in high or low temperature environment, especially in cold areas, PVC pipes are prone to brittle cracks. And HDPE pipe due to its excellent toughness, can withstand the greater impact force, and can maintain good performance under extreme temperature conditions, which makes its service life in extreme climate longer.

2.2 Flexibility and installation convenience

The flexibility of HDPE pipeline is stronger than that of PVC pipeline, and it can better adapt to the change and settlement of soil, especially in areas with frequent earthquakes or unstable soil, HDPE pipeline is more effective in preventing fracture. In contrast, PVC pipes are more fragile and easy to break due to the pressure of soil or the vibration of an earthquake. Therefore, in the complex geological environment, HDPE pipe has more advantages.

3. Comparison with steel pipe: more corrosion resistance, reduce maintenance costs

Steel pipe has always been one of the commonly used materials in industrial pipelines, especially in oil, gas and water supply systems. Steel pipe has a high compressive strength, but its corrosion resistance is poor, which makes the steel pipe in many cases need to be anti-corrosion treatment, increasing the cost of construction and maintenance.

3.1 Corrosion resistance

The steel pipe will be corroded by factors such as water, soil and oxygen in the air, especially in a humid or chemically corrosive environment, and the service life of the steel pipe will be greatly shortened. In order to cope with the corrosion problem, the steel pipe usually needs to be coated with anti-corrosion paint or undergo other anti-corrosion treatment, which not only increases the cost of installation and maintenance, but also requires regular inspection and replacement of the anti-corrosion layer.

In contrast, HDPE pipe corrosion resistance is extremely strong, it is not attacked by water, soil or most chemicals, so there is little need for additional anti-corrosion treatment. The long-term use of HDPE pipes does not cause corrosion problems, thus reducing maintenance costs.

3.2 Weight vs. ease of installation

The weight of the steel pipe is relatively large, and the difficulty of handling and installation is also high. The HDPE pipe because of its lightweight characteristics, the installation required less labor and equipment, the construction process is more simple, can save a lot of time and cost. In addition, because the HDPE pipeline does not need to be welded, only a simple electrothermal welding or mechanical connection can ensure a firm joint, further improving the installation efficiency.

4. Comparison with cast iron pipe: higher durability and safety

Cast iron pipe was once a common piping material used in water supply and drainage systems, especially in early urban infrastructure construction. However, with the advancement of technology, HDPE pipes have gradually taken the place of cast iron pipes in many applications, especially in modern urban water and sewage systems.

4.1 Corrosion resistance and rust resistance

Cast iron pipe has good compressive strength, but it is very susceptible to the influence of moisture, oxygen and other factors in the external environment, resulting in rust and corrosion. In humid environments or areas with strong chemical corrosion, the service life of cast iron pipes is shorter. In contrast, HDPE pipes are almost impervious to corrosion and can be used in harsh environments for a long time.

4.2 Weight and shipping issues

The weight of cast iron pipe is much higher than that of HDPE pipe, and the cost of transportation and installation is also higher. Especially in longer pipe systems, the transportation and installation cost of cast iron pipes is often much higher than that of HDPE pipes. In addition, the connection process of cast iron pipe is complex and the installation time is long, while the installation of HDPE pipe is simpler, shortens the construction cycle and reduces the total cost of the project.

5. The comprehensive advantages of HDPE pipeline: the best choice for long-term investment

By comparing with PVC pipe, steel pipe and cast iron pipe, we can clearly see the superiority of HDPE pipe in many aspects. It not only performs well in corrosion resistance, impact resistance, ease of installation, etc., but also its lower maintenance cost and longer service life make it the preferred material for many pipeline projects.

Supplier

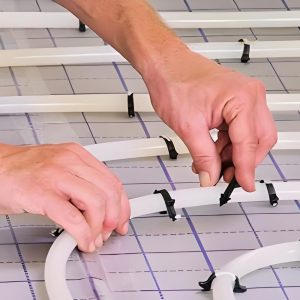

Luoyang Datang Energy Tech Co., Ltd. is a professional manufacturer and supplier of pipes and fittings. We offer PPR pipes, PVC pipes, PE pipes, and floor heating pipes and fittings for all types of pipes, with high quality and competitive prices. If you have any inquiries about pipes and fittings, please do not hesitate to contact us. You can click on the product to get in touch with us.