LUOYANG DATANG ENERGY TECH CO.,LTD

How to build a leak-proof HDPE piping system?

In modern fluid transportation projects, the performance of HDPE pipe and fittings depends 50% on the quality of the connection. As the world’s leading provider of HDPE piping system solutions, we delve into three core connectivity technologies to help you build a safe and leak-proof HDPE piping system.

First. Why connection technology is the lifeblood of HDPE system?

Although HDPE (high density polyethylene) pipe and fittings have excellent flexibility, if the connection process is not proper, it will lead to:

Stress concentration at the interface leads to the risk of tube explosion

Microscopic leakage causes an average annual loss of 3% to 5% of the medium

Temperature difference deformation leads to the overall failure of the pipeline system

The use of scientific connection scheme can achieve:

Joint strength ≥ 90% of the strength of the pipe body

50 years service life with zero leakage

Reduce maintenance costs by more than 30%

Second, the depth of the three mainstream connection technologies

1. Butt Fusion

Application scenario

Large diameter main pipeline above DN90 (water supply/gas/industrial pipeline)

Linear section long distance laying

Technical highlight

Molecular level fusion: Through 220±5℃ precise temperature control, the connected interface polyethylene molecular chains penetrate each other

Four-stage process:

1. End milling (roughness Ra≤0.01mm)

2. Heating plate contact (pressure 0.15MPa)

3. Heat absorption stage (time calculated according to wall thickness)

4. Switch butt joint (pressure holding cooling to below 50℃)

Comparison of advantages

| Parameters | Hot melt butt | Traditional welding |

| Connection strength | 95% | 70% |

| Construction efficiency | 15 minutes/piece | 45 minutes/piece |

| Equipment input | From $2500 | From $850 |

2. Electrofusion

DN20-DN315 small and medium pipe diameter

Complex space work (pipe gallery/crossing structure)

Smart upgrade solutions

Our fourth generation fusion pipe fitting integration:

Chip-level temperature monitoring: real-time tracking of 10 temperature measurement points

Self-compensating pressure system: Automatically adjusts the expansion margin

Qr code traceability: Scan code to obtain welding parameter history

Operation five-step method:

1. Scrape off the oxide layer (depth 0.1-0.2mm)

2. Install positioning fixture (deviation < 1°)

3. Scan code to activate welder parameters

4. Intelligent step heating (39V±2V)

5. Cool naturally for 120 minutes

Data verification criteria:

Flanging height ≥ 10% of pipe wall thickness

The resistance wire is fully embedded in the melt

Cooling shrinkage < 0.3%

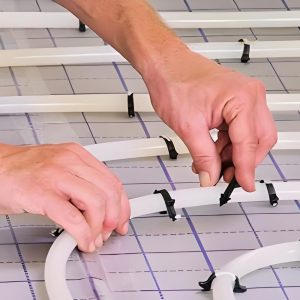

3. Mechanical Joints

Applicable scenarios

Temporary works (construction site/emergency repair)

Dissimilar material transition (HDPE with steel/cast iron pipe)

Innovative seal construction

Triple locking system:

1. Stainless steel clamp (304/316L optional)

2. EPDM wedge seal ring (temperature -40℃~120℃)

3. Anti-slip tooth design (anti-axial displacement)

Installation precautions

The bolts should be tightened three times in diagonal order

Final torque value: DN100 pipe fitting 35N·m±10%

The elasticity of the seal ring should be tested annually.

Third, How to choose the best connection scheme?

Refer to the following decision matrix:

| Dimensions of consideration | Hot melt butt | Electric fusion connection | Mechanical connections |

| Initial investment costs | high | In the | low |

| Long-term maintenance costs | low | low | high |

| Construction space requirement | big | small | Flexible |

| Personnel skill requirements | high | In the | low |

| Detachable | Not | No | Can be |

Forth, Our technology enabling system

Choose our connectivity solutions and you’ll get:

Intelligent Construction package: Includes infrared temperature detector + digital torque wrench + tube end processor

Digital operation and maintenance platform: real-time monitoring of interface stress state, warning potential risks

Certification training system: IHSSE Connection Engineer certificate issued worldwide

Fifth. Professional advice to industry users

1. Municipal engineering gives priority to hot melt docking to ensure permanent connection of the backbone network

2. Chemical pipeline recommended fusion + flange composite connection, taking into account sealing and maintenance convenience

3. Agricultural irrigation can use quick installation mechanical joints, to meet the seasonal disassembly needs

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a professional manufacturer and supplier of pipes and fittings. We offer PPR pipes, PVC pipes, PE pipes, and floor heating pipes and fittings for all types of pipes, with high quality and competitive prices. If you have any inquiries about pipes and fittings, please do not hesitate to contact us. You can click on the product to get in touch with us.