LUOYANG DATANG ENERGY TECH CO.,LTD

How To Install HDPE Gas Pipe Correctly?

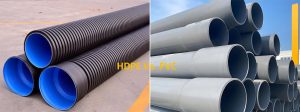

Polyethylene (HDPE) gas pipe has become the material of choice for gas delivery systems due to its excellent performance and economy. As a leading PE gas pipeline producer in China, we not only provide high-quality products that meet international standards, but also provide OEM (original equipment manufacturing) and ODM (original design manufacturing) services to our customers to meet the diverse needs of the global market.

First, the core advantages of HDPE Gas Pipe:

1. Corrosion resistance and long life

PE material has natural resistance to chemical corrosion and electrochemical corrosion, especially suitable for wet, acid-alkali soil environment. Compared with traditional metal pipes, its service life can reach more than 50 years, and the maintenance cost can be reduced by more than 60%.

2. High flexibility and impact resistance

The elongation at break of PE pipeline exceeds 350%, which can effectively resist the deformation caused by foundation settlement or earthquake. The performance is still stable under the extreme temperature of -60℃ to 40℃.

3. Lightweight and convenient construction

The density is only 1/8 of the steel pipe, and the transportation and installation efficiency is significantly improved. The use of hot melt or electric fusion connection technology, no need for complex welding equipment, construction speed increased by 30%-50%.

4. Environmental protection and safety

No harmful substances are emitted in the production process, and 100% recyclable. The inner wall of the pipeline is smooth, the gas flow resistance is small, and the risk of leakage is extremely low, which meets the EU EN 1555 and China GB 15558 standards.

Second, Installation process of HDPE Gas Pipe

1. Preparation before installation

Design planning: Design the direction of the pipeline according to the gas flow, pressure level (such as SDR11/SDR17) and terrain conditions, avoid underground obstacles, and ensure that the buried depth is ≥ 0.8m (road) or ≥ 0.6m (sidewalk).

Material acceptance: check the appearance of the pipeline (no scratches, bubbles), specification certificate (including raw material melting index, oxidation induction time test report), and sampling for hydrostatic strength test (80℃/165h).

Personnel training: Construction personnel need to hold PE pipeline welding operation certificate, master the hot melt machine temperature control (220℃±10℃) and pressure parameters (heat absorption pressure 0.15MPa, cooling pressure 0.02MPa).

2. Trench excavation and foundation treatment

When mechanical excavation is used, 20cm manual cleaning layer is reserved at the bottom of the trench to ensure the base is smooth.

Lay 10cm thick sand cushion layer on rock or hard ground to prevent pipe scratches.

3. Pipe laying and connection

A.Hot melt butt (DN≥90mm) :

1. Milling the end face to flat, the amount of misalignment < 10% wall thickness.

2. The heating plate temperature is set at 210℃-230℃, and the heating time is calculated according to the wall thickness ×10 seconds /mm.

3. Maintain constant pressure at the endothermic stage, switch time ≤5 seconds, cooling time ≥ wall thickness ×1min/mm.

B.Electric fusion connection (DN≤315mm) :

1. Scrape off the oxide layer and mark the insertion depth clearly.

2. Set the voltage (usually 36V-48V) according to the resistance value of the fuse sleeve, and the welding time is automatically calibrated.

Quality inspection: the flanging height should reach 1/3 of the wall thickness of the tube, and the electric melting observation hole should be pushed out.

4. Pressure test and backfill

The strength test (1.5 times the working pressure, 4h pressure regulation) and the tightness test (1.15 times the working pressure, 24h pressure drop ≤1%) are carried out in sections.

Backfill using lamination compaction method, each layer thickness ≤20cm, the initial backfill using fine sand to protect the pipeline.

The scientific installation of Polyethylene (HDPE) Gas Pipe is the core link to ensure gas safety, and choosing a Chinese pipes and fittings manufacturer with leading technology can better obtain the triple advantages of cost, quality and service.

Supplier

Luoyang Datang Energy Tech Co., Ltd. is a professional manufacturer and supplier of pipes and fittings. We offer PPR pipes, PVC pipes, PE pipes, and floor heating pipes and fittings for all types of pipes, with high quality and competitive prices. If you have any inquiries about pipes and fittings, please do not hesitate to contact us. You can click on the product to get in touch with us.