LUOYANG DATANG ENERGY TECH CO.,LTD

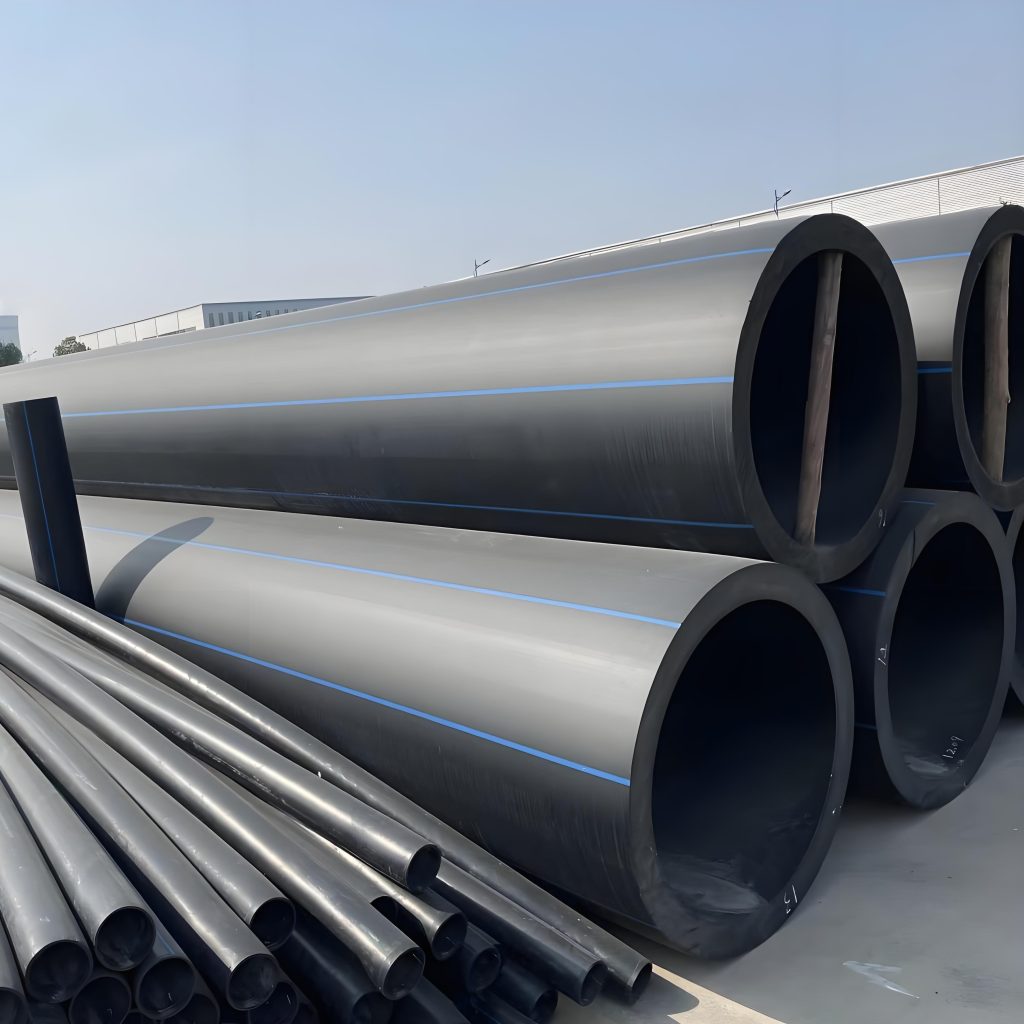

High-Temperature Resistant HDPE Gas Pipe

PRODUCT PARAMETERS

Description

Introduction of HDPE Gas Pipe

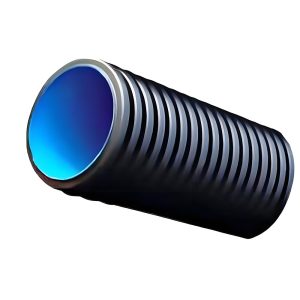

Polyethylene Gas Pipe (PE gas pipe, short for PE gas pipe) is a pipeline system made of high density polyethylene (HDPE) or medium density polyethylene (MDPE) as raw materials through extrusion molding process, specially designed for the transportation of natural gas, liquefied petroleum gas (LPG) and other gas media. Compared with traditional metal pipes, PE gas pipe has become the preferred material in the field of global gas transportation due to its characteristics of light weight, corrosion resistance, strong impact resistance and long life.

Details of HDPE Gas Pipe

Corrosion resistance: PE material has natural resistance to chemical corrosion, electrochemical corrosion and soil microbial erosion, without additional anti-corrosion treatment.

Flexibility and shock resistance: The pipeline has high flexibility, which can adapt to external deformation such as terrain settlement or earthquake, and reduce the risk of leakage.

Long life service: the design life can reach more than 50 years, far more than the metal pipeline (usually 20-30 years).

Convenient construction: light weight (only 1/8 of the steel pipe), support trenchless construction (such as directional drilling), greatly reduce installation costs.

Good sealing: using hot melt connection technology, the interface strength is consistent with the pipe body, and the potential gas leakage is eliminated.

Environmental safety: non-toxic and tasteless, in line with drinking water contact standards, and 100% recyclable.

HDPE Gas Pipe technical indicators:

| Indicators | Parameter requirements |

| Density (g/cm³) | ≥0.94 (HDPE) |

| Melting index (g/10min) | ≤0.5 (190 ° C, 5kg) |

| Long-term hydrostatic strength (MPa) | PE80:8.0 (20 ° C, 50 years)PE100: 10.0 (20 ° C, 50 years) |

| Elongation at break (%) | ≥350 |

| Resistance to environmental stress cracking (h) | ≥1000 (80℃, 4.6MPa) |

| Oxidation induction time (min) | ≥20 (200 ° C) |

Specifications of HDPE Gas Pipe

1.Material grading

PE80: Medium density polyethylene, suitable for medium and low pressure gas transmission (≤0.4MPa).

PE100: High-density polyethylene, with higher strength and pressure resistance (up to 1.0MPa), suitable for high pressure long distance transportation.

2. Pipe size

| Outside diameter (mm) | SDR value | Working pressure (MPa) | Wall thickness range (mm) |

| 20-63 | SDR11 | 0.4-0.6 | 2.3-5.8 |

| 75-180 | SDR17.6 | 0.2-0.4 | 4.3-10.3 |

| 200-630 | SDR11 | 0.8-1.0 | 18.2-57.2 |

Note: SDR (Standard Dimension Ratio) is the ratio of the outer diameter of the pipe to the wall thickness, and the smaller the value, the stronger the pressure resistance.

3. Standard length

Straight pipe: 6m, 12m (non-standard length can be customized).

Coil pipe: 50m-200m (suitable for small diameter pipe, easy to transport and construction).

4. Color identification

Black pipe body + yellow stripe: international common gas pipeline identification.

Other colors can be customized according to customer requirements (subject to local regulations).

5. International standard certification:

ISO 4437: International standard for buried polyethylene piping systems for gas applications.

EN 1555: European standard for polyethylene piping for gas transmission.

ASTM D2513: American Society for Materials and Testing Standard for Gas Piping.

GB 15558.1-2015: China’s National Standard for polyethylene pipes for Gas use.

Applications of HDPE Gas Pipe

1. Urban gas network

Municipal gas main lines and residential pipelines.

Gas supply system for industrial and commercial users.

2. Industrial gas transmission

Industrial gas distribution for chemical plants, power stations, etc.

LNG/LPG storage and distribution station connection pipeline.

3 Rural and remote areas

Distributed gas supply system.

Bio-gas engineering gas pipeline.

4. Special environment

Earthquake prone areas: Use flexibility to reduce the risk of fracture.

Highly corrosive soil: Longer service life instead of metal pipes.

Water crossing: low buoyancy, excellent water pressure resistance.

Packing and Shipment

Pipe dia. dn20-63mm be in coils with 100m/200m length

Pipe dia. Dn75-1200mm be packed in bars with 5.8m or 11.8m length

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co.Ltd was established in 2015 and located in High-tech development zone, Luoyang City, covers a large area with state-of-the-art facilities. Our government offers a supportive environment, including convenient transportation and access to essential resources. Since inception in 2015, we have been committed to excellence in pipes and fittings, continuously innovating to meet market demands.

If you need PPR Pipes and Fittings,Please feel free to contact us(sales@pipesandfittings.net)

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

FAQ of HDPE Gas Pipe

Q1: How long is the service life of HDPE Gas Pipe?

A: Under standard working pressure and environmental conditions, the design life of PE gas pipe is 50 years. The actual life is affected by the installation quality, soil environment and maintenance.

Q2: Can HDPE Gas Pipe withstand high temperature?

A: PE gas pipe long-term operating temperature limit is +40℃, short-term (such as maintenance welding) can withstand +60℃. It is recommended to use heat-resistant materials or add insulation layer in high temperature environment.

Q3: How to connect HDPE Gas Pipe?

A: Electrofusion and Butt Fusion are mainly used, which need to be operated by professional technicians to ensure tightness.

Q4: Is the HDPE Gas Pipe environmentally friendly?

A: PE material is non-toxic and harmless, the production process is pollution-free, and can be 100% recycled, in line with EU RoHS and REACH environmental protection standards.

Q5: What are the disadvantages of PE100 Gas Pipe compared with metal pipe?

A: PE pipes have poor UV resistance (need to be buried) and limited high temperature resistance. However, its comprehensive cost performance still has significant advantages in the gas field.

REQUEST A QUOTE

RELATED PRODUCTS

-

Email: sales@pipesandfittings.net

-

WeChat: +86 18337900677